Contents

Choosing the perfect print method for your project might feel like navigating a maze, but we’re here to make it easy. While methods like screen printing, DTG, and embroidery might ring a bell, there’s actually a whole world of print options, each with its own perks and limitations. Your choice depends on multiple factors: budget, garment type, design complexity, and order size.

To make this decision less daunting, we’ve compiled a guide to help you pick the right one for your project.

Now if print methods sound like tech jargon to you, don’t sweat it! Many reputable T-shirt printing companies will have a team of in-house experts that will help ensure you get the right process for your order, ensuring you get optimal results. But for those who love diving into the details, let’s explore your options.

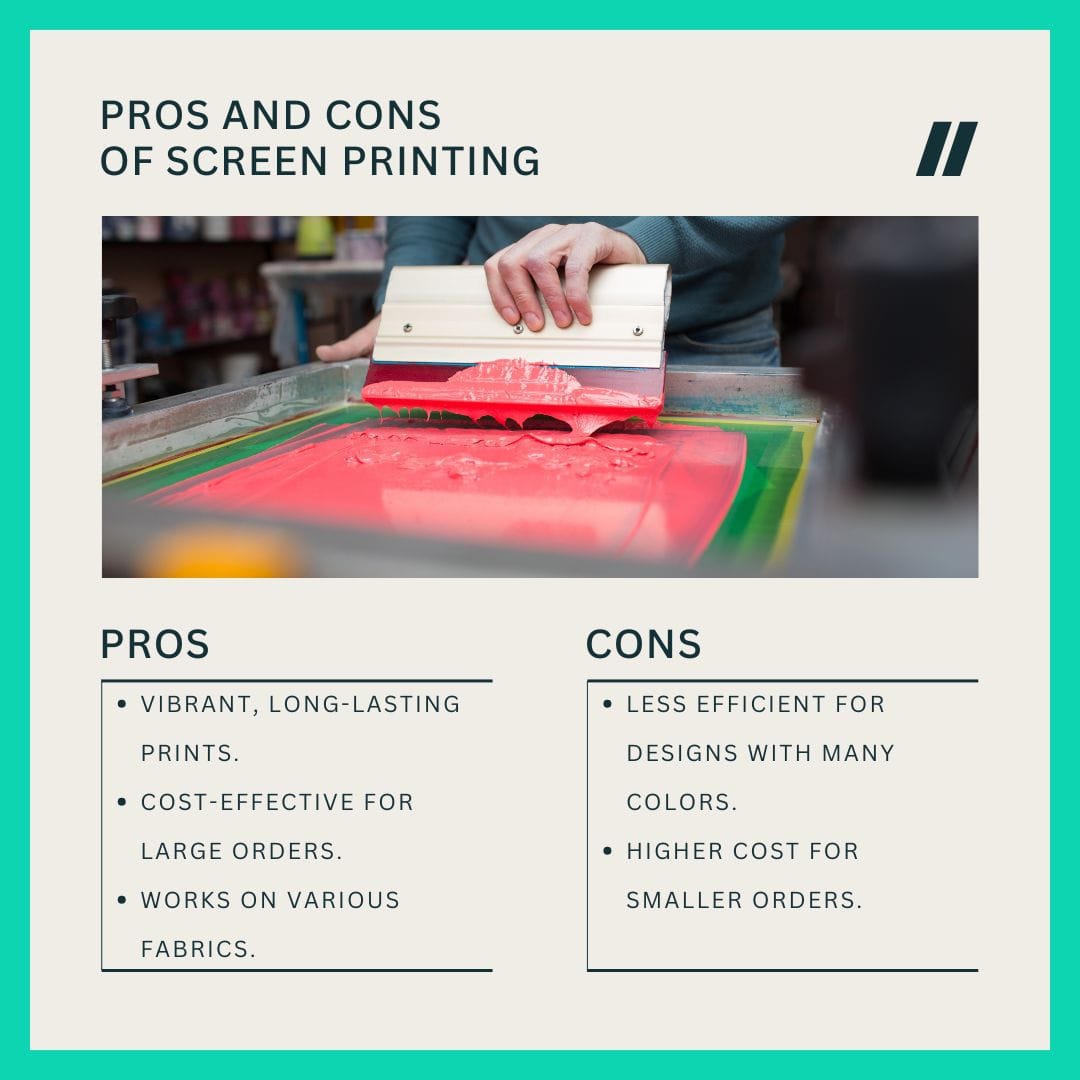

Screen Printing: The Go-To for Bulk Orders and Bold Colors

Screen printing remains a fan favorite for large orders and dominates the print industry. It offers vibrant, durable colors that can be Pantone-matched for brand consistency. It’s perfect for designs with limited colors and becomes increasingly cost-effective when printing over 50 products. You’ll often find it used on cotton and a variety of other fabrics, making it a flexible choice for most garments. This is arguably one of the most well-known print methods, due to it’s extensive use in retail and band merchandise.

How It Works: Your design gets transferred to a screen, and ink is pushed through the mesh using a squeegee. Each color in your design requires a separate screen, which adds to the cost but allows for bold, true-to-life results.

Suitable for you if:

- You’ve got 50+ products.

- Your design uses only a few colors.

- You want Pantone-matched colors for branding.

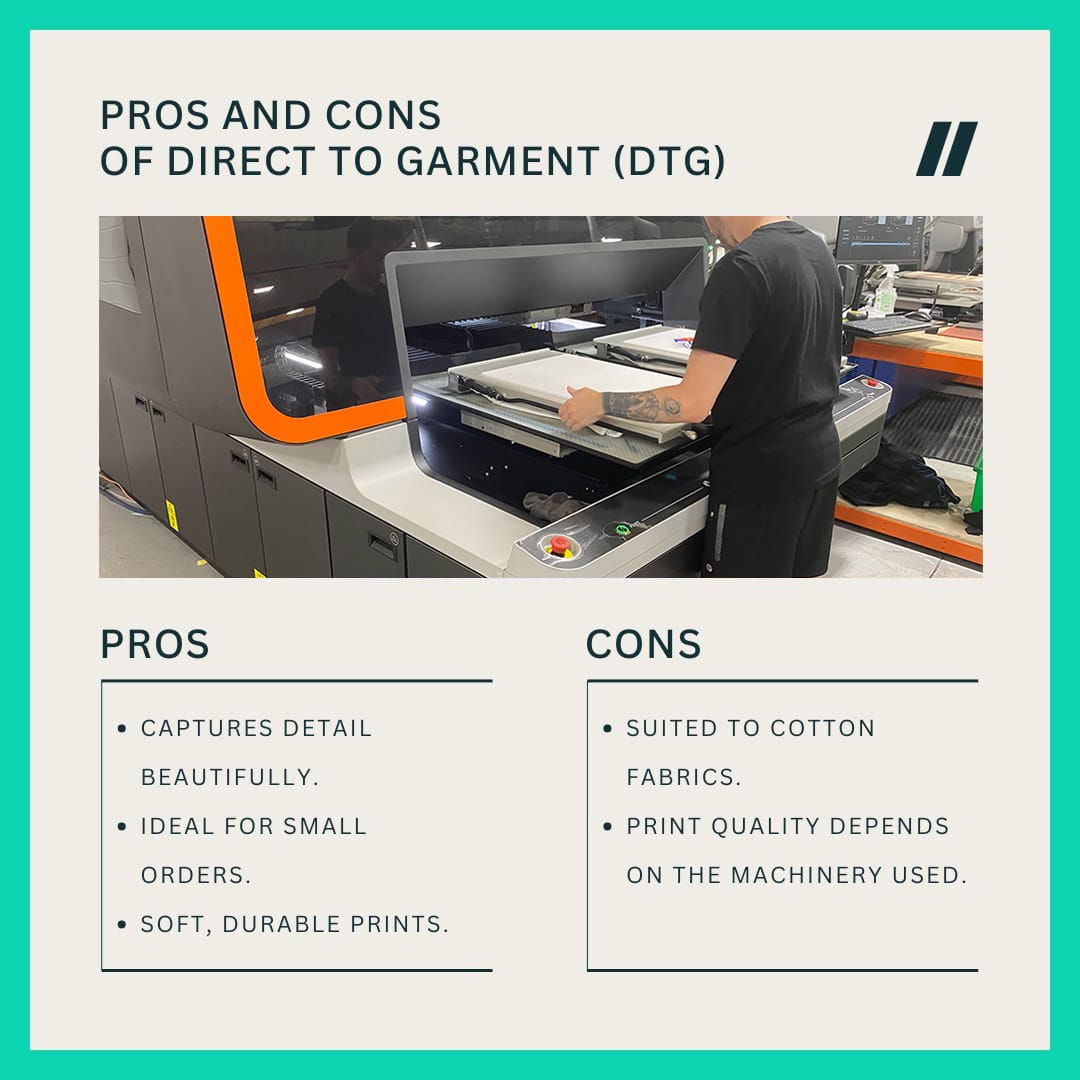

Direct to Garment (DTG): The Hero for Small Orders and Detailed Designs

You might not be familiar with DTG printing, but it's been a game-changer for the textile industry, fueling the massive growth of print-on-demand clothing. DTG is all about precision, especially for complex designs with many colors or photorealistic prints. Unlike screen printing, it sprays ink directly onto the fabric, embedding it into the fibers, resulting in a soft finish. DTG is especially great for short runs or smaller quantities, which is why it’s been so prevalent in the world of print-on-demand. While it’s limited to mostly cotton garments, it produces high-quality results, comparable to that of screen printing when done right.

How It Works: Think of it as an industrial version of your home inkjet printer, except this one can be as large as your car (on the bigger machines) and prints directly onto garments! It’s perfect for capturing intricate designs that traditional methods might struggle with.

Suitable for you if:

- You’re ordering fewer than 50 units.

- You’ve got a detailed or colorful design.

- You prefer a softer, more natural print finish.

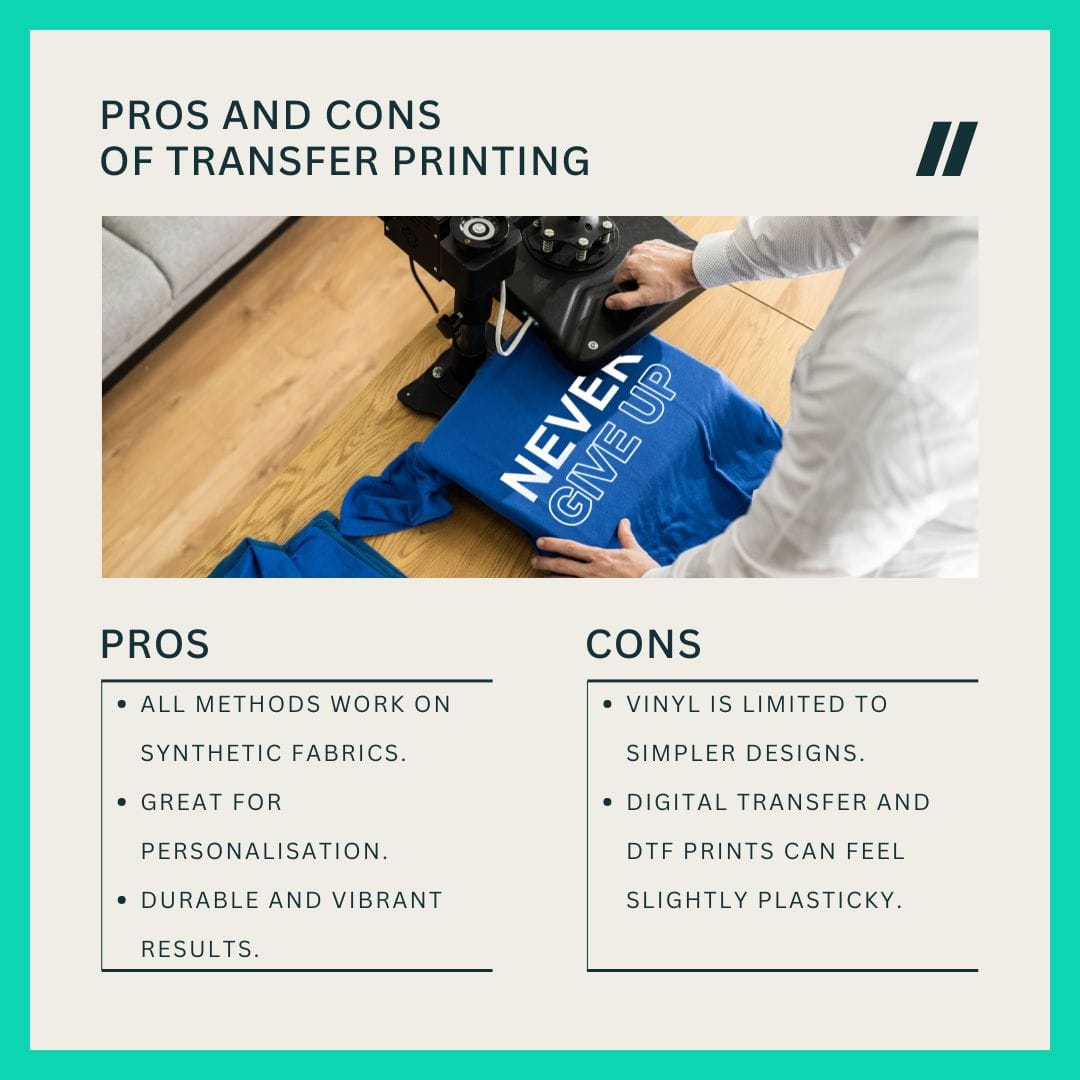

Transfer Printing: Versatile Solutions for Synthetic Fabrics and Personalisation

When it comes to printing on synthetic fabrics like polyester, transfer printing methods offer flexible and durable results.

Digital Transfer Printing works well for both simple and complex designs, bonding your artwork to the fabric using heat. It’s ideal for personalised orders, like team uniforms or hi-vis workwear, and delivers vibrant, long-lasting prints.

Vinyl Printing is another heat-based method, perfect for simple, single coloured designs such as names or numbers on workwear. Vinyl is cut from coloured sheets and pressed onto the garment, offering exceptional durability, especially on synthetic fabrics.

Direct-to-Film (DTF) is a newer transfer method, where the design is printed onto a film, coated with adhesive powder, and then heat-pressed onto the fabric. It delivers a strong, flexible print that feels softer than vinyl and is perfect for both small-scale and detailed designs. This is quickly dominating the transfer market, with a study we undertook showing that search interest in DTF printing has skyrocketed, the percentage growth was a staggering 7420% between 2020 and 2024.

Suitable for you if:

- You need a method that works well with synthetic fabrics.

- You’re looking for personalised designs or small, detailed orders.

Each method offers unique benefits, so selecting the right one depends on your project’s complexity and fabric needs.

Dye Sublimation: The Winner for All-Over Printing

If you want full, edge-to-edge designs on your garments, dye sublimation is the only method that delivers. Perfect for polyester fabrics, it bonds the ink to the fibers, resulting in a soft-touch, vibrant finish that doesn’t peel or fade. It’s particularly popular for custom fashion items, staff uniforms, and merchandise. It delivers a finish so lightweight it’s as if the garment hasn’t even been printed - which is perfect if you’ve got all over-coverage.

How It Works: Your design is digitally printed onto transfer paper. Then, with heat, the ink transitions into a gas, bonding directly with the fabric fibers to create an all-over print.

Suitable for you if:

- You need all-over designs.

- You’re working with polyester garments.

- You want a design that won’t fade or peel.

Embroidery: The Premium Choice for Durability and a Professional Finish

Embroidery isn’t just about style; it’s about longevity. If you’re after something professional that can withstand heavy wear, embroidery delivers. Perfect for logos and branding, it gives a raised, premium finish that works best on polo shirts, jackets, and hoodies. However, it’s less ideal for complex or highly detailed designs due to the thread limitations.

How It Works: Your design is digitized and loaded into an embroidery machine, which then sews the design into the fabric using high-quality threads.

Suitable for you if:

- You want something professional and long-lasting.

- You’re ordering in bulk.

- Your design is simple and doesn’t require intricate details.

Sustainability: Making Eco-Friendly Choices

Sustainability is a critical component in the world of fashion, so it’s essential to consider the environmental impact of different printing methods. Much like choosing a print method, it can be a bit of a maze to get right. Screen printing can contain phthalates, which are endocrine-disrupting chemicals, safe alternatives are available, but always check your print partner is using them. DTG printing produces minimal waste since it uses only the necessary ink for each design, making it a more sustainable choice for small orders. The process is also water based, making it an great eco-friendly option. Meanwhile, Dye Sublimation requires polyester garments which are a type of plastic, while there are recycled polyester T-shirt options available, we’d only typically recommend this when it’s essential. For a more eco-conscious approach, always opt for organic T-shirts and water-based or biodegradable inks when possible and when it delivers the overall optimal sustainability outcome, for the entire lifecycle of the garment.

In addition, reducing excess inventory with low minimum order volume print methods like DTG or transfer printing can help lower waste, as garments are only produced when needed in micro-production runs or on-demand. If sustainability is a priority for your project, discussing your options with a printing partner who offers green materials and processes is crucial. They can guide you toward more environmentally-friendly choices that still deliver exceptional print quality.

By considering sustainability alongside your project’s design and fabric needs, you’ll make choices that align with both your brand’s ethics and your customers’ expectations for eco-friendly products.

Can Quality Vary Depending on the Printing Company?

It is important to note, print quality is often determined by the quality of the machines and inks used. This is why you’ll often find some offer a really cheap price, while others command a more premium price, on the exact same garments.

To provide some context, you can buy a manual print machine for less than £1000, compared to the machines we use which can be as much as £500,000 each. The quality achieved by the higher end machines and inks are substantially better than those on the cheaper end. As a result you’ll find some printers deliver results that feel a bit like your stag-do T-shirts, while others feel like a retail product.

If you're unsure about a T-shirt printer's equipment, check their case studies and clients. Printing for major brands and retailers often indicates high-quality standards.

Final Thoughts: Picking the Right Method

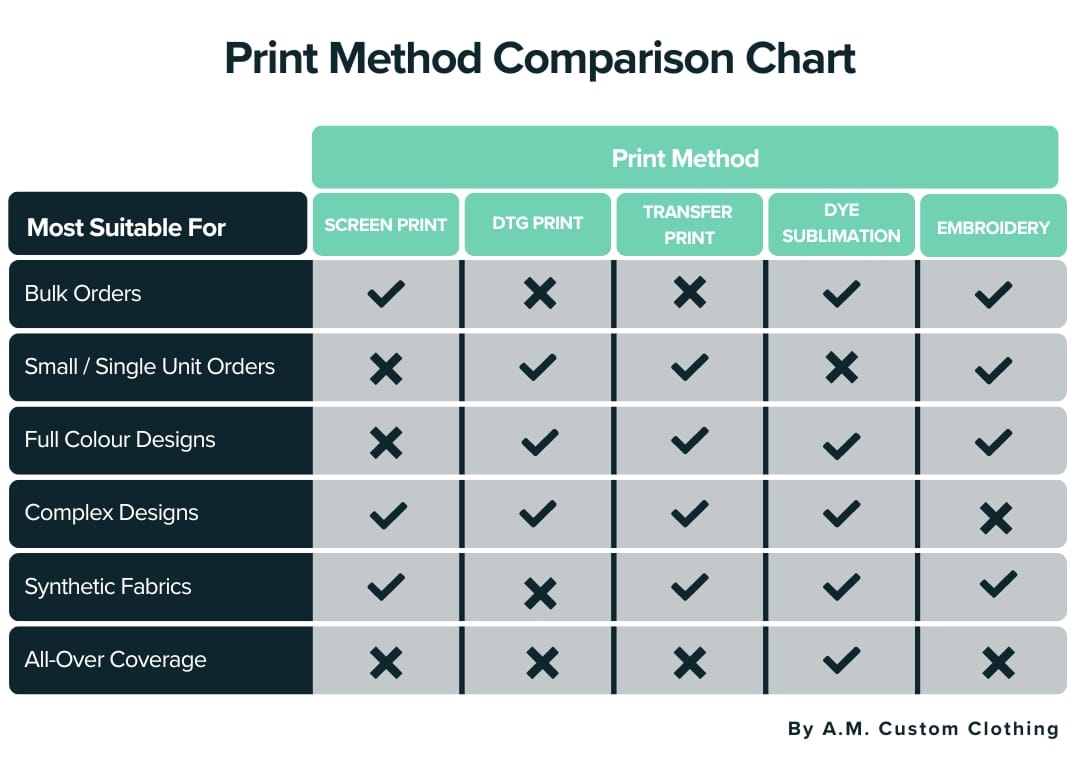

The key takeaway here? There’s no universally recommended print method, it’s all about finding what works for your project’s needs. From bold, large-batch screen printing to the precision of DTG, each method brings something different to the table. You can save the graph below, so you can quickly and easily navigate which process is most suited to your current and upcoming projects.

Lastly, when it comes to choosing a suitable print method, I’d always recommend consulting with your T-shirt printing supplier, to get their opinion on the most suitable process for your order type, to help ensure you get the option most appropriate for your needs.