Contents

In the dynamic world of fashion, the journey from concept to consumer is a complex and intricate process that involves numerous stages and stakeholders. From the initial design spark to the final product landing in the hands of fashion enthusiasts, the fashion supply chain plays a pivotal role in shaping the industry's landscape.

This comprehensive guide delves into the intricacies of fashion supply chain management, exploring the key stages, emerging trends, and the transformative impact of technology. Whether you are a seasoned industry professional, an aspiring designer, or simply curious about the inner workings of the fashion world, this guide is your go-to resource for understanding how fashion products make their way from the drawing board to the runway and beyond.

Join us as we unravel the layers of the fashion supply chain, examining the challenges, innovations, and sustainable practices that are shaping the future of this dynamic and ever-evolving industry. From sourcing raw materials to leveraging cutting-edge technologies, we invite you on a journey through the heart of fashion's intricate web, where creativity meets logistics, and style meets substance. Let's embark on this exploration together and discover the fascinating world behind the garments we love. Welcome to the ultimate guide to the fashion supply chain!

What is fashion supply chain and why it is important

The fashion supply chain refers to the entire process of creating and delivering fashion products, from the initial design and manufacturing of garments to their distribution and retailing. It involves a series of interconnected stages, including design, sourcing of raw materials, production, transportation, distribution, retail, and ultimately, consumption by end-users. Each stage of the supply chain contributes to the creation and delivery of fashion goods.

The fashion supply chain is important for several reasons:

- Efficiency and Cost Management: A well-organized supply chain helps optimize production processes, reduce costs, and improve overall efficiency.

- Globalization of Production: Fashion supply chains often span multiple countries, allowing for the globalization of production. Different countries contribute to various stages of the supply chain based on their strengths and expertise.

- Time-to-Market: Rapid changes in fashion trends require a quick response from the industry. A streamlined supply chain helps reduce time-to-market, enabling fashion brands to stay relevant and competitive.

- Sustainability: The fashion industry has been under scrutiny for its environmental impact. A sustainable supply chain can help minimize waste, reduce energy consumption, and promote ethical practices throughout the production process.

- Collaboration and Communication: Effective communication and collaboration among various stakeholders in the supply chain are essential for smooth operations. This includes designers, manufacturers, suppliers, logistics providers, and retailers.

In summary, the fashion supply chain is a complex network of processes that ensures the efficient and timely production and distribution of fashion products. Its proper management is critical for the success of fashion brands in a competitive and dynamic industry.

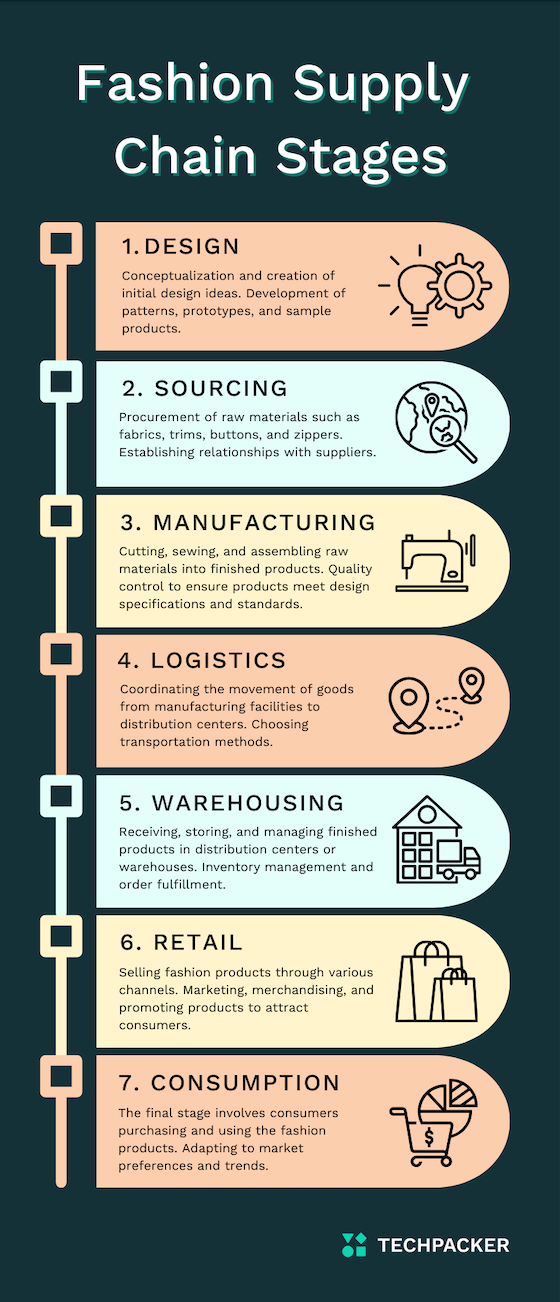

What are the key stages of the fashion supply chain?

Fashion supply chain stages are interconnected, and the efficiency of each stage impacts the overall effectiveness of the fashion supply chain. Effective coordination and communication among stakeholders at each stage are crucial for the successful delivery of fashion products to the end consumer.

The key stages of the fashion supply chain are as follows:

1. Design and Development:

- Conceptualization and creation of initial design ideas.

- Development of patterns, prototypes, and sample products.

2. Raw Material Sourcing:

- Procurement of raw materials such as fabrics, trims, buttons, and zippers.

- Establishing relationships with suppliers and ensuring the quality and sustainability of materials.

3. Manufacturing/Production:

- Cutting, sewing, and assembling raw materials into finished products.

- Quality control to ensure products meet design specifications and standards.

- Production may occur in factories, often located in different regions or countries.

4. Logistics and Transportation:

- Coordinating the movement of goods from manufacturing facilities to distribution centers.

- Choosing transportation methods, such as sea freight, air freight, or land transport.

- Managing the logistics and supply chain network to optimize efficiency.

5. Distribution and Warehousing:

- Receiving, storing, and managing finished products in distribution centers or warehouses.

- Inventory management and order fulfillment to meet demand.

- Ensuring products are ready for timely delivery to retailers.

6. Retail:

- Selling fashion products through various channels, including physical stores and online platforms.

- Marketing, merchandising, and promoting products to attract consumers.

- Managing sales transactions, customer service, and returns.

7. Consumption:

- The final stage involves consumers purchasing and using the fashion products.

- Consumer feedback and data are important for brands to adapt to market preferences and trends.

Types of supply chains in the fashion industry

In the fashion industry, different types of supply chains exist to accommodate various business models, production methods, and distribution strategies. The choice of a particular supply chain type depends on factors such as the brand's positioning, target market, production scale, and sustainability goals.

Here are some common types of supply chains in the fashion industry:

1. Traditional Supply Chain:

- The sequential and linear model, where each stage follows the next in a fixed order (design, sourcing, production, distribution, retail).

- May involve long lead times and large production batches.

2. Fast Fashion Supply Chain:

- Emphasizes quick response to changing fashion trends.

- Short production cycles, frequent design changes, and rapid delivery to retail.

- Often involves lower-cost production and high inventory turnover.

3. Lean Supply Chain:

- Focuses on minimizing waste, reducing excess inventory, and improving efficiency.

- Just-in-time production and tight inventory control are key components.

- Aims to meet customer demand without overproduction.

4. Sustainable and Ethical Supply Chain:

- Emphasizes environmentally friendly and socially responsible practices.

- Involves the use of sustainable materials, ethical labor practices, and reduced environmental impact.

- Transparency in the supply chain is crucial.

5. Luxury Supply Chain:

- Characterized by high-quality materials, craftsmanship, and exclusivity.

- Production often involves smaller batches and may be more localized.

- Emphasis on brand image and customer experience.

6. Vertical Integration:

- A company owns and controls multiple stages of the supply chain, from production to retail.

- Can provide greater control over quality, costs, and speed to market.

- Common among luxury brands and some fast-fashion retailers.

7. Agile Supply Chain:

- Designed to quickly respond to changes in consumer demand and market trends.

- Flexibility and adaptability are key, allowing for adjustments in production and distribution.

- Often leverages advanced technology and data analytics.

8. Circular Supply Chain:

- Focuses on minimizing waste and promoting recycling and reuse.

- Involves designing products with recyclability in mind and implementing take-back programs.

- Aims to create a closed-loop system, reducing the environmental impact of fashion.

9. Collaborative Supply Chain:

- Involves close collaboration between different stakeholders in the supply chain.

- Information sharing, communication, and joint decision-making are emphasized.

- Enhances efficiency and responsiveness to market changes.

The fashion industry is dynamic, and companies may adopt a combination of these supply chain types based on their specific goals and market positioning. As sustainability and ethical considerations gain prominence, more fashion brands are exploring and implementing environmentally and socially responsible practices within their supply chains.

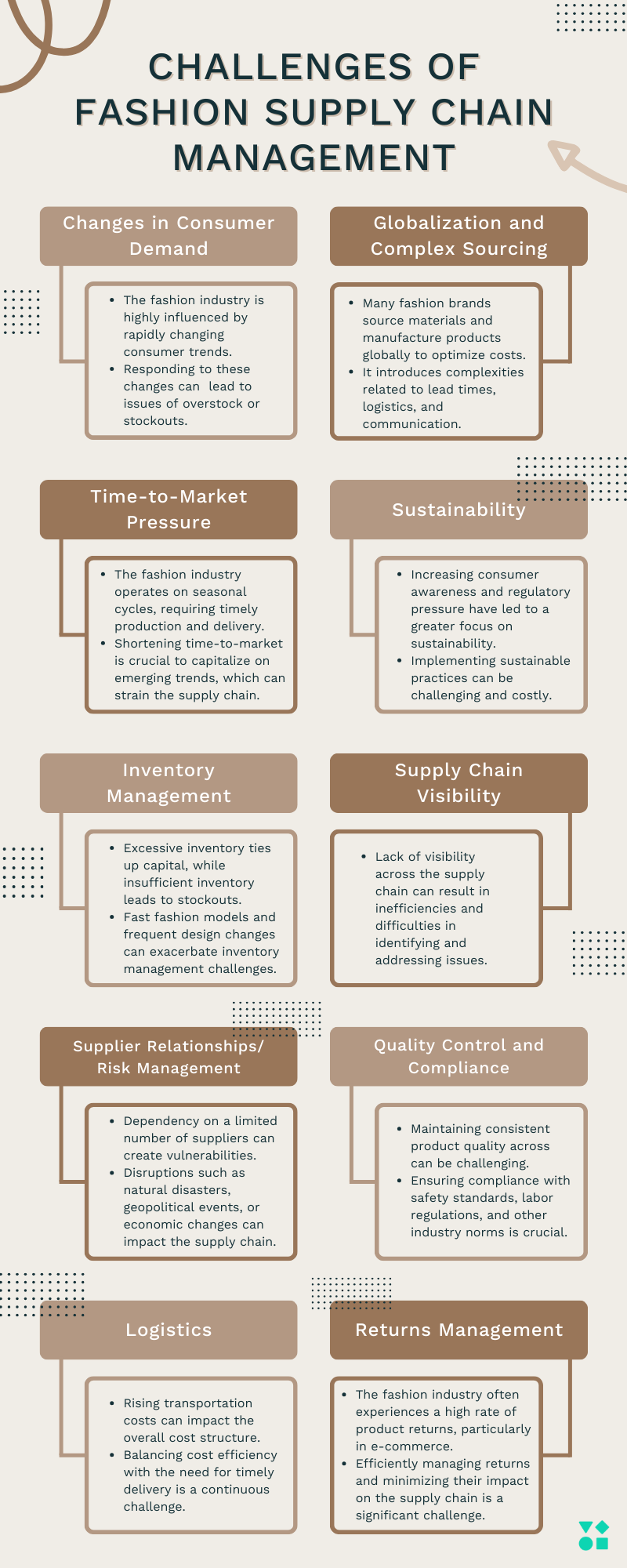

Challenges of fashion supply chain management

Fashion supply chain management faces several challenges, reflecting the complexity of the industry and the dynamic nature of consumer preferences. Some of the key challenges include:

1. Rapid Changes in Consumer Demand:

- The fashion industry is highly influenced by rapidly changing consumer trends and preferences.

- Forecasting and responding to these changes can be challenging, leading to issues of overstock or stockouts.

2. Globalization and Complex Sourcing:

- Many fashion brands source materials and manufacture products globally to optimize costs.

- Managing a global supply chain introduces complexities related to lead times, logistics, and communication with suppliers.

3. Seasonality and Time-to-Market Pressure:

- The fashion industry operates on seasonal cycles, requiring timely production and delivery.

- Shortening time-to-market is crucial to capitalize on emerging trends, which can strain the supply chain.

4. Sustainability and Ethical Practices:

- Increasing consumer awareness and regulatory pressure have led to a greater focus on sustainability and ethical practices.

- Implementing sustainable sourcing, production, and distribution practices can be challenging and costly.

5. Inventory Management:

- Maintaining the right amount of inventory is a delicate balance. Excessive inventory ties up capital, while insufficient inventory leads to stockouts.

- Fast fashion models and frequent design changes can exacerbate inventory management challenges.

6. Supply Chain Visibility:

- Lack of visibility and transparency across the supply chain can result in inefficiencies and difficulties in identifying and addressing issues.

- Real-time data and analytics are essential for effective decision-making.

7. Supplier Relationships and Risk Management:

- Dependency on a limited number of suppliers can create vulnerabilities.

- Disruptions such as natural disasters, geopolitical events, or economic changes can impact the supply chain.

8. Quality Control and Compliance:

- Maintaining consistent product quality across different production facilities can be challenging.

- Ensuring compliance with safety standards, labor regulations, and other industry norms is crucial.

9. Logistics and Transportation Costs:

- Rising transportation costs and global shipping challenges can impact the overall cost structure.

- Balancing cost efficiency with the need for timely delivery is a continuous challenge.

10. Technological Integration:

- Implementing and integrating advanced technologies, such as RFID, blockchain, and AI, into traditional supply chain processes can be complex.

- Resistance to technological change and the need for substantial investments are common challenges.

11. Returns Management:

- The fashion industry often experiences a high rate of product returns, particularly in e-commerce.

- Efficiently managing returns and minimizing their impact on the supply chain is a significant challenge.

Addressing these challenges requires a combination of strategic planning, technological innovation, collaboration among supply chain partners, and a proactive approach to sustainability and ethical considerations. As the industry continues to evolve, supply chain managers need to adapt and find solutions to these dynamic challenges.

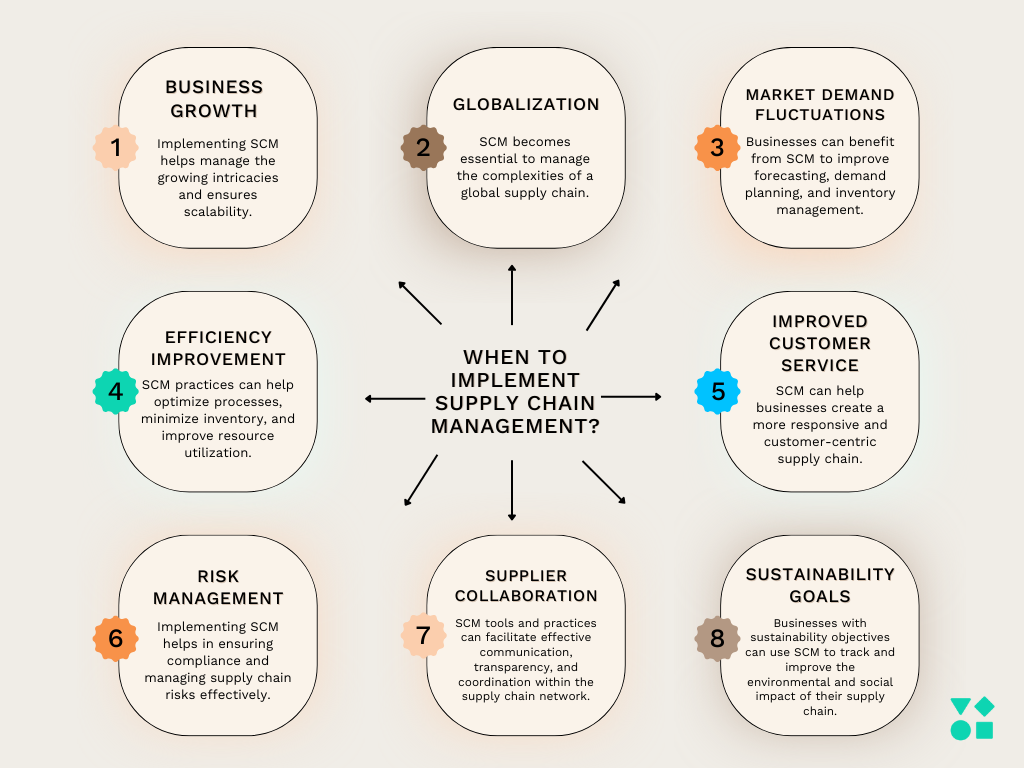

When to implement supply chain management

Implementing supply chain management (SCM) is crucial for businesses looking to streamline operations, enhance efficiency, and improve overall performance.

Here are some key situations or circumstances when organizations should consider implementing supply chain management:

1. Business Growth or Expansion:

- When a business is experiencing growth or planning to expand, the complexity of its supply chain often increases. Implementing SCM helps manage the growing intricacies and ensures scalability.

2. Globalization:

- If a business is expanding its operations internationally or sourcing materials and products from global suppliers, SCM becomes essential to manage the complexities of a global supply chain.

3. Increased Product Variety or Complexity:

- Introducing a wider range of products or dealing with complex product configurations can strain existing supply chain processes. SCM helps in handling diverse product portfolios efficiently.

4. Market Demand Fluctuations:

- Businesses facing unpredictable market demand or seasonality can benefit from SCM to improve forecasting, demand planning, and inventory management.

5. Cost Pressures and Efficiency Improvement:

- When there is a need to control costs, reduce waste, and enhance overall efficiency, SCM practices can help optimize processes, minimize inventory, and improve resource utilization.

6. Improved Customer Service and Satisfaction:

- Businesses aiming to enhance customer service, shorten lead times, and improve order fulfillment can leverage SCM to create a more responsive and customer-centric supply chain.

7. Compliance and Risk Management:

- Increasing regulatory requirements and the need for risk mitigation strategies make SCM critical. Implementing SCM helps in ensuring compliance and managing supply chain risks effectively.

8. Technological Advancements:

- With the advent of advanced technologies like IoT, RFID, AI, and blockchain, businesses can leverage SCM solutions to improve visibility, traceability, and decision-making throughout the supply chain.

9. E-commerce Integration:

- For businesses entering or expanding in the e-commerce space, SCM becomes essential to handle the unique challenges associated with online retail, including order fulfillment, returns management, and real-time inventory updates.

10. Supplier Collaboration:

- When collaboration with suppliers becomes a strategic focus, SCM tools and practices can facilitate effective communication, transparency, and coordination within the supply chain network.

11. Continuous Improvement Initiatives:

- Organizations committed to a culture of continuous improvement can implement SCM to identify inefficiencies, measure performance, and implement strategies for ongoing optimization.

12. Sustainability Goals:

- Businesses with sustainability objectives can use SCM to track and improve the environmental and social impact of their supply chain, including responsible sourcing and waste reduction.

In summary, businesses should consider implementing supply chain management when they face challenges related to growth, globalization, increased complexity, market dynamics, cost pressures, customer expectations, compliance, technological advancements, e-commerce integration, supplier collaboration, continuous improvement, and sustainability goals. SCM is a strategic investment that can yield significant benefits in terms of efficiency, competitiveness, and customer satisfaction.

Future of fashion supply chain management

The future of fashion supply chain management is likely to be shaped by ongoing technological advancements, changing consumer behaviors, and an increased focus on sustainability. Here are some trends and potential developments that may influence the future of fashion supply chain management:

1. Digital Transformation and Technology Integration:

- Greater adoption of advanced technologies, such as artificial intelligence (AI), machine learning, big data analytics, and the Internet of Things (IoT), to enhance visibility, decision-making, and overall efficiency in the supply chain.

2. Blockchain for Transparency and Traceability:

- Increased use of blockchain technology to provide transparent and traceable supply chains, helping to verify the authenticity of products, ensure ethical sourcing, and improve overall accountability.

3. Predictive Analytics and Demand Forecasting:

- Continued advancements in predictive analytics to improve demand forecasting, enabling fashion brands to anticipate trends, optimize inventory levels, and reduce the risk of overstock or stockouts.

4. Sustainable and Circular Supply Chains:

- Growing emphasis on sustainability throughout the fashion supply chain, including sustainable sourcing, eco-friendly manufacturing processes, and the development of circular supply chains that minimize waste and promote recycling.

5. Fast Fashion Evolving into Sustainable Fashion:

- Shifts in the fast fashion model towards more sustainable practices, with a focus on reducing environmental impact, promoting fair labor practices, and offering products with longer life cycles.

6. 3D Printing and On-Demand Manufacturing:

- Increased adoption of 3D printing technology for on-demand manufacturing, allowing for more flexible and localized production, reducing the need for large inventories, and enabling customization.

7. E-commerce and Omnichannel Integration:

- Further integration of e-commerce platforms and traditional retail channels into omnichannel strategies, with a focus on seamless customer experiences, real-time inventory visibility, and efficient order fulfillment.

8. Supplier Collaboration and Resilience:

- Closer collaboration with suppliers and the development of more resilient supply chains to better respond to disruptions, whether they are caused by geopolitical events, natural disasters, or other unforeseen circumstances.

9. Ethical and Social Responsibility:

- Increasing attention to ethical and social responsibility, with consumers demanding greater transparency and accountability from fashion brands regarding labor practices, sourcing, and overall corporate responsibility.

10. Robotic Process Automation (RPA) in Warehousing:

- Implementation of robotic process automation in warehouses for tasks such as picking, packing, and sorting, improving efficiency and reducing labor-intensive processes.

11. Regulatory Compliance and Standards:

- Continued focus on meeting and adapting to evolving regulatory standards related to environmental impact, labor practices, and product safety.

12. Skills and Talent Development:

- Recognition of the need for skilled professionals in supply chain management, including those with expertise in data analytics, technology integration, and sustainability practices.

The future of fashion supply chain management will likely involve a combination of technology-driven solutions, sustainable practices, and a commitment to meet evolving consumer expectations. As the industry navigates challenges, there will be opportunities for innovation and improvement in the way fashion products are designed, produced, and delivered to consumers.

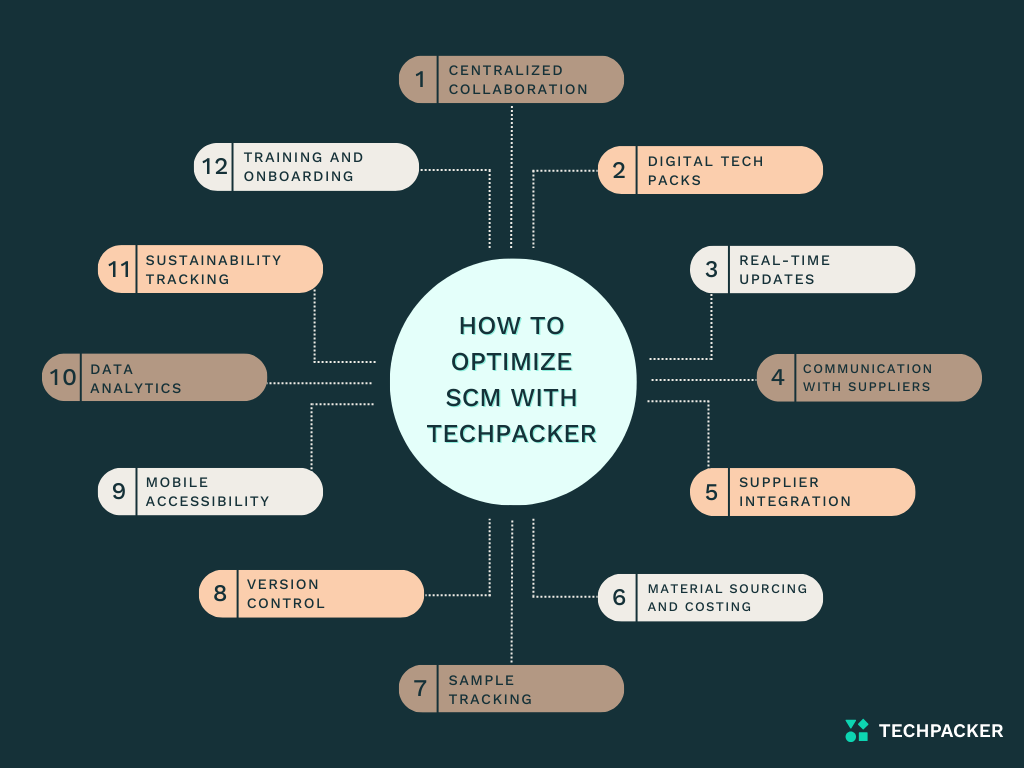

How to optimize supply chain management with Techpacker

Techpacker is a cloud-based Product Lifecycle Management (PLM) platform designed to streamline the fashion product development process. It has been a valuable tool for optimizing supply chain management in the fashion industry.

Here's how you can use Techpacker PLM to enhance various aspects of supply chain management:

1. Centralized Communication and Collaboration:

- Techpacker provides a centralized platform for collaboration between designers, product developers, and manufacturers. This helps in reducing communication gaps and ensuring that all stakeholders are on the same page.

2. Digital Tech Packs:

- Replace traditional paper-based tech packs with digital versions on Techpacker. This not only reduces the risk of errors but also allows for faster updates and revisions, improving overall efficiency in the product development process.

3. Real-time Updates:

- With Techpacker, teams can access real-time updates on the status of each product in the development pipeline. This helps in tracking progress, identifying bottlenecks, and making informed decisions to keep the supply chain moving smoothly.

4. Collaboration with Suppliers:

- The platform enables seamless collaboration with suppliers, allowing them to view and interact with digital tech packs. This can lead to better understanding, fewer misunderstandings, and faster production processes.

5. Supplier Integration:

- Integrate Techpacker with other supply chain management tools or ERPs to create a more connected and streamlined supply chain. This integration can help in managing inventory, order processing, and other key aspects of the supply chain.

6. Material Sourcing and Costing:

- Utilize Techpacker to manage material sourcing by including detailed information about fabrics, trims, and other components in the tech packs. The platform also supports costing calculations, aiding in budgeting and cost management.

7. Sample Tracking:

- Keep track of sample production and approvals using Techpacker. This helps maintain visibility into the sample development process, reducing lead times, and ensuring that product samples meet quality standards.

8. Version Control:

- Techpacker offers version control features, allowing users to keep track of changes made to tech packs over time. This helps in avoiding confusion and ensures that everyone is working with the latest and approved version of a design.

9. Mobile Accessibility:

- The platform's mobile accessibility allows stakeholders to access and review tech packs on the go. This can be particularly useful for teams that are geographically dispersed or need to collaborate outside of the office.

10. Data Analytics for Decision-making:

- Leverage the data analytics features of Techpacker to gain insights into the product development process. Analyzing trends and performance metrics can help in making data-driven decisions to optimize the supply chain.

11. Sustainability Tracking:

- Use Techpacker to include information related to sustainable practices in the supply chain. This could involve specifying eco-friendly materials, production processes, or adherence to certain sustainability standards.

12. Training and Onboarding:

- Techpacker can be used as a training tool for new team members or suppliers. The platform's user-friendly interface makes it easier for individuals to quickly learn and adopt digital processes, reducing onboarding time.

By incorporating Techpacker into the fashion supply chain management process, businesses can enhance collaboration, reduce lead times, and improve overall efficiency, contributing to a more streamlined and optimized supply chain.

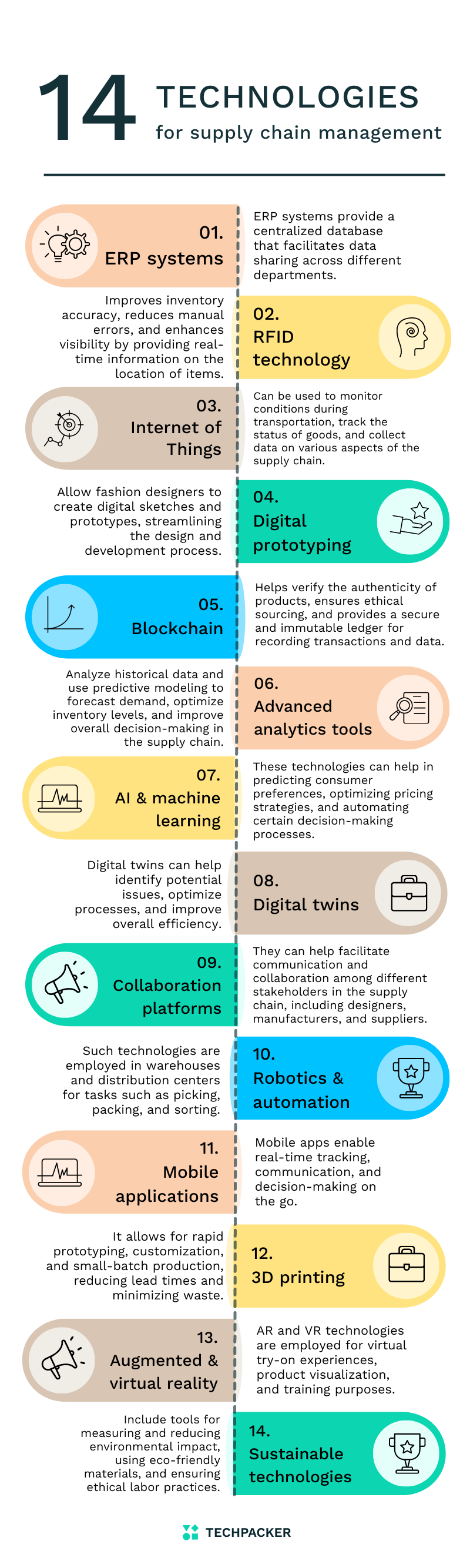

Technologies that are used for fashion supply chain management

Various technologies are employed in fashion supply chain management to enhance efficiency, visibility, and overall performance. These technologies help streamline processes, reduce costs, and adapt to the dynamic nature of the fashion industry. Here are some key technologies used for fashion supply chain management:

1. Enterprise Resource Planning (ERP) Systems:

- ERP systems integrate and manage various business processes, including inventory management, order processing, and financials. They provide a centralized database that facilitates data sharing across different departments.

2. Radio-Frequency Identification (RFID):

- RFID technology enables the tracking of products and materials throughout the supply chain. It improves inventory accuracy, reduces manual errors, and enhances visibility by providing real-time information on the location of items.

3. Internet of Things (IoT):

- IoT devices, such as sensors and connected devices, can be used to monitor conditions during transportation, track the status of goods, and collect data on various aspects of the supply chain. This data can be leveraged for analytics and decision-making.

4. Digital prototyping:

- Online vector editors like Repsketch may allow fashion designers to create digital sketches and prototypes, streamlining the design and development process. This digital representation can be shared with other stakeholders in the supply chain for feedback and approval.

5. Blockchain:

- Blockchain technology enhances transparency and traceability in the supply chain. It helps verify the authenticity of products, ensures ethical sourcing, and provides a secure and immutable ledger for recording transactions and data.

6. Advanced Analytics and Predictive Modeling:

- Data analytics tools analyze historical data and use predictive modeling to forecast demand, optimize inventory levels, and improve overall decision-making in the supply chain.

7. Artificial Intelligence (AI) and Machine Learning (ML):

- AI and ML algorithms are used for demand forecasting, trend analysis, and pattern recognition. These technologies can help in predicting consumer preferences, optimizing pricing strategies, and automating certain decision-making processes.

8. Digital Twin Technology:

- Digital twin technology creates a virtual replica of physical assets, allowing businesses to simulate and monitor the entire supply chain. This can help identify potential issues, optimize processes, and improve overall efficiency.

9. Collaboration and Communication Platforms:

- Cloud-based collaboration tools facilitate communication and collaboration among different stakeholders in the supply chain, including designers, manufacturers, and suppliers. Platforms like Techpacker enable digital collaboration on product development.

10. Robotics and Automation:

- Robotics and automation technologies are employed in warehouses and distribution centers for tasks such as picking, packing, and sorting. This helps improve efficiency and reduce manual labor in logistics operations.

11. Mobile Applications:

- Mobile apps enable real-time tracking, communication, and decision-making on the go. This is especially useful for supply chain managers, field personnel, and others who need access to information outside the office.

12. 3D Printing:

- 3D printing technology is used for on-demand and localized manufacturing. It allows for rapid prototyping, customization, and small-batch production, reducing lead times and minimizing waste.

13. Augmented Reality (AR) and Virtual Reality (VR):

- AR and VR technologies are employed for virtual try-on experiences, product visualization, and training purposes. They enhance the customer experience and can be utilized in various stages of the supply chain.

14. Sustainable Technologies:

- Technologies that support sustainability in the supply chain include tools for measuring and reducing environmental impact, using eco-friendly materials, and ensuring ethical labor practices.

The integration of these technologies into fashion supply chain management helps businesses address challenges, improve agility, and stay competitive in an ever-evolving industry. Adopting a combination of these tools allows fashion companies to create more resilient, transparent, and efficient supply chains.

Summary

As we conclude our ultimate guide to the fashion supply chain, we hope this exploration has provided you with valuable insights into the intricate processes that shape the fashion industry.

In our journey together, we've uncovered the challenges faced by the industry, the transformative role of technology, and the rising tide of sustainability that is reshaping the landscape. The fashion supply chain is more than just a logistical process; it's a convergence of creativity, innovation, and responsible practices that define the very essence of the fashion world.

As the industry continues to adapt and innovate, we encourage you to stay informed, embrace the opportunities presented by technology, and champion sustainability. The future of fashion supply chain management is in the hands of those who recognize the power of collaboration, transparency, and a commitment to creating a fashion ecosystem that respects both the artistry of design and the well-being of our planet.