Contents

If you work in product development, you have probably opened a sample and thought, "That is not the seam I asked for." Or a factory has written back asking you to explain a seam that seemed obvious when you added it to the tech pack.

After working with designers, factories and product teams for a long time, I started to notice something obvious that we rarely talk about. Seams are everywhere, yet we do not have a common language for them. That matters because seams control fit, durability, comfort and sometimes even brand identity. When seam instructions are fuzzy, every unclear instruction silently eats time, budget and trust.

This post starts a conversation about what would happen if we actually standardized seams. I do not mean forcing one look on every garment. I mean protecting design intent so creativity survives the journey to production. This is the first post in our series on standardization in fashion. I hope you like it, and I hope it sparks ideas you can bring back to your team.

Why Seam Communication Is Still a Problem in Fashion Manufacturing

Across my career, I have rarely seen two people describe the same seam the exact same way. This is not a skills problem. It is a communication problem.

The same seam name can mean different constructions to:

- Designers

- Factories

- Quality teams

- Vendors across regions

Here are a few patterns I see almost everywhere:

- People use different terms for the same thing: A clean finish might mean turned-under edge to one person and invisible stitch to someone else.

- Written instructions rely heavily on experience: "Bagged out, 1/4 inch seam allowance, topstitched" is clear to some, confusing to others.

- Factories interpret based on what they know: Vendors often lean on their own default construction methods unless your diagram is very precise.

Belu, the founder of ABC Seams, explained it perfectly during our conversation:

"ABC Seams was created to solve a common problem in the apparel industry, and that is the lack of consistency in explaining the sewing seams and the construction details."

That line perfectly captures the heart of the problem. This is why standardizing seams in fashion matters.

What Does “Standardizing Seams in Fashion” Actually Mean?

When I talk about standardization, people sometimes assume I want to force everyone to use the same seam in every garment. That is not the goal at all.

Here is what I mean when I talk about standardizing seams:

- Shared naming or coding system: So when we say a seam name, it carries the same meaning for everyone involved.

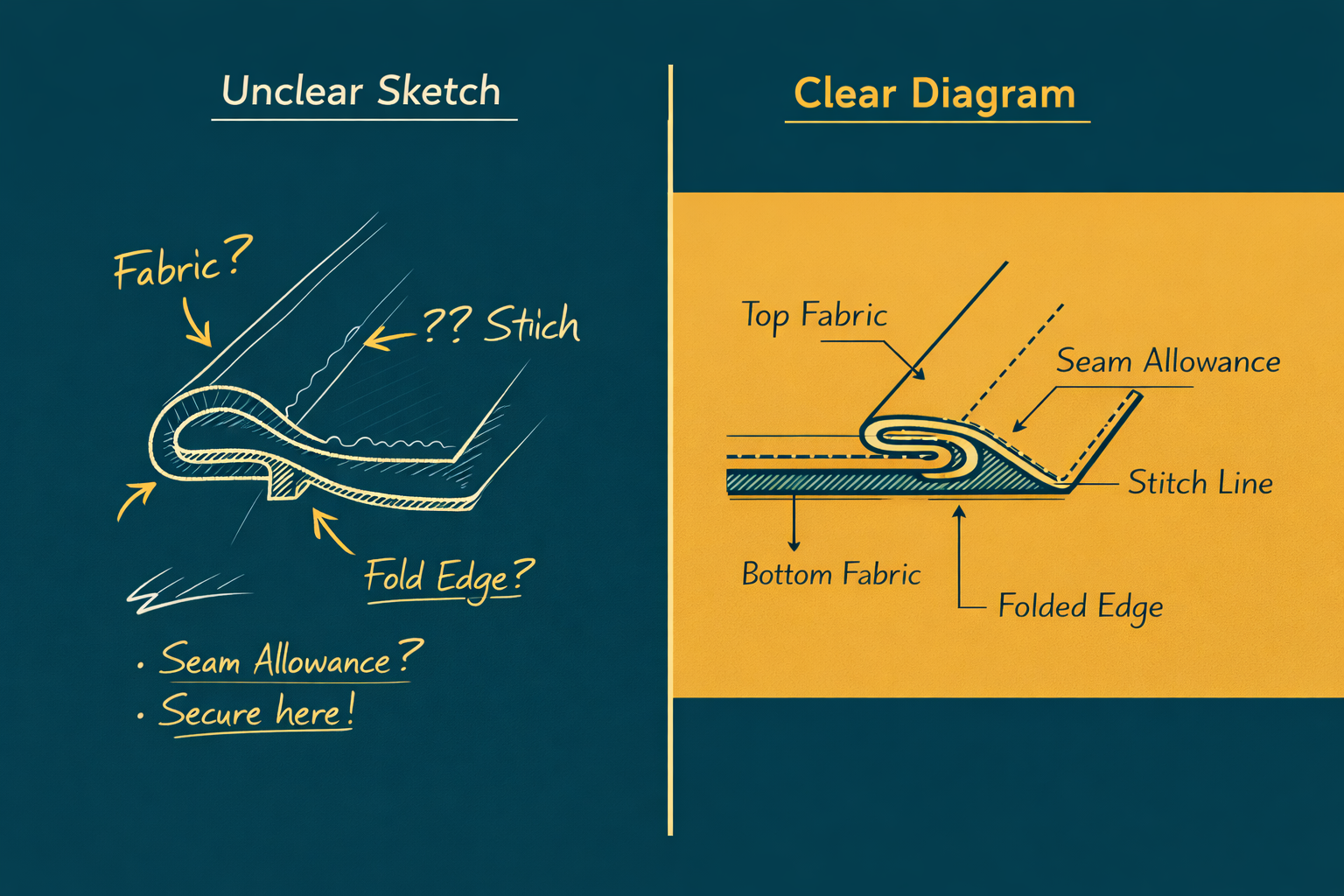

- Shared diagram: Because diagrams remove 90 percent of guesswork.

- Shared interpretation: A designer in New York and a factory in Vietnam should visualize the same thing.

- Shared default logic: Thread type, SPI, needle, seam allowance and basic stitch assumptions should be known, not assumed.

And this does not take creativity away. If anything, it protects your original intention.

Standardization protects creativity. As Belu put it,

"So the goal with ABC Seams - we create a system with the goal, with the idea of improving the communication between designers, technicians, or product developers, pattern makers, and manufacturers."

When the basics are clear, people can spend attention on design, not on clarifying the basics.

Why Construction Diagrams Are Central to Seam Standardization

Written seam instructions will always fall short because seams are physical. You cannot fully describe three layers folding over each other with text alone.

Diagrams solve this. They show:

- The exact cross-section: Where layers meet or overlap.

- Hidden construction: Stay stitches, understitches, reinforcing stitches.

- Direction: Especially important for knits, bias cuts or high-stress areas.

As Belu described how she uses diagrams,

"You put a drawing and just a coat. You can explain that to to your manufacturer or to your technician, also designers and technicians."

That is the point. A visual reference translates intent.

The Cost of Not Standardizing Seams

Let me share a quick story. A brand I worked with had two vendors producing the same dress. Everything looked identical except the neckline seam. One factory folded it under; the other used a binding. No one caught it until stores complained that some dresses had more bulk at the shoulder.

And this was not negligence. It was an interpretation. Multiply this across styles, seasons and factories, and the cost is massive:

- Sampling delays: One unclear seam can add days or weeks to development.

- Production inconsistencies: Same spec, different factories, different results - a nightmare for QC.

- Fit and performance issues: Wrong seam construction changes drape, increases bulk, or weakens stress points.

- Quality control hassles: QC flags that are rooted in misinterpretation are expensive and demoralizing.

- Customer dissatisfaction: Consumers do not articulate construction problems, but they feel them.

The industry loses millions each year simply because we do not standardize how we talk about seams.

When we asked Belu for concrete impact, she told us about a brand where ABC Seams produced measurable gains. In her words, after a brand started using the ABC Seams sketches,

"They could improve the development process by about thirty percent. So they require fewer samples because you always have things to improve with the prototypes."

That is a big operational saving and a better place to spend your time, focusing on fit rather than fighting over construction.

How Seam & Diagram Standardization Can Work in Practice

This is my favorite part of the conversation because there are already great examples we can learn from.

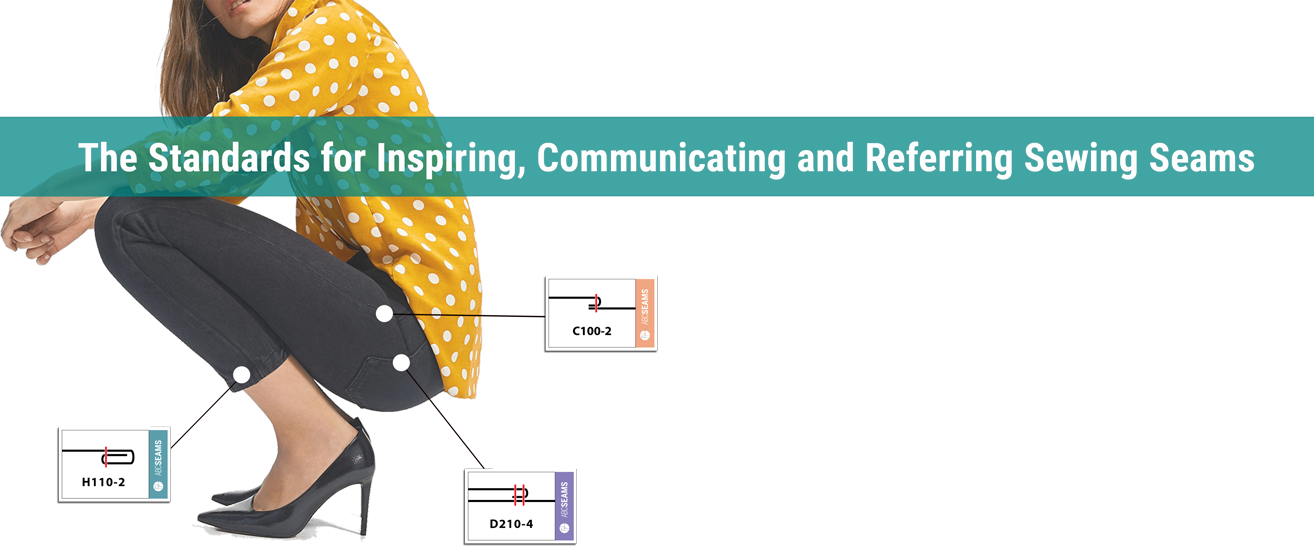

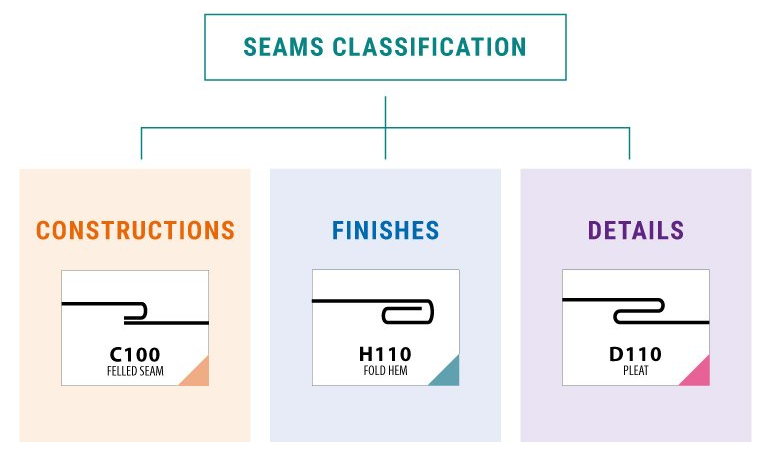

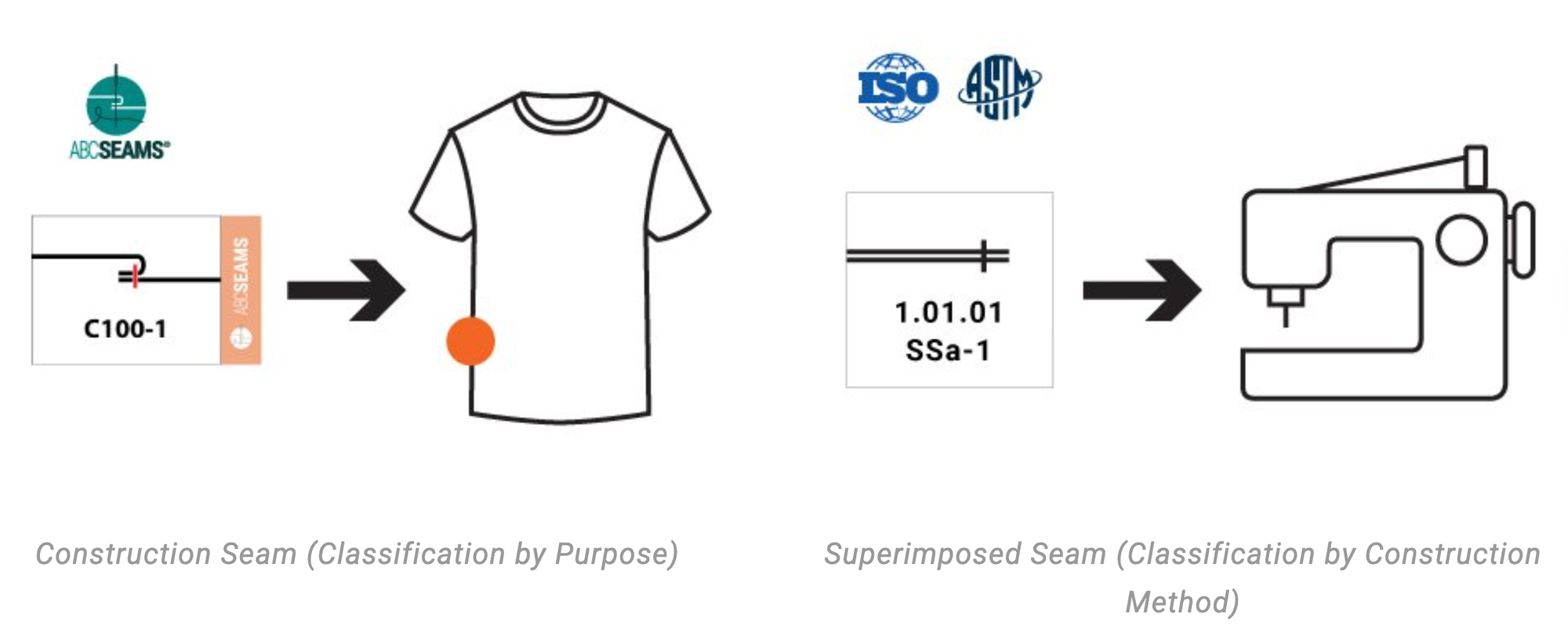

ABC Seams (ASCS): A Visual + Code-Based Seam Language

ABC Seams is probably the clearest real-world example of a modern seam standardization system.

They offer:

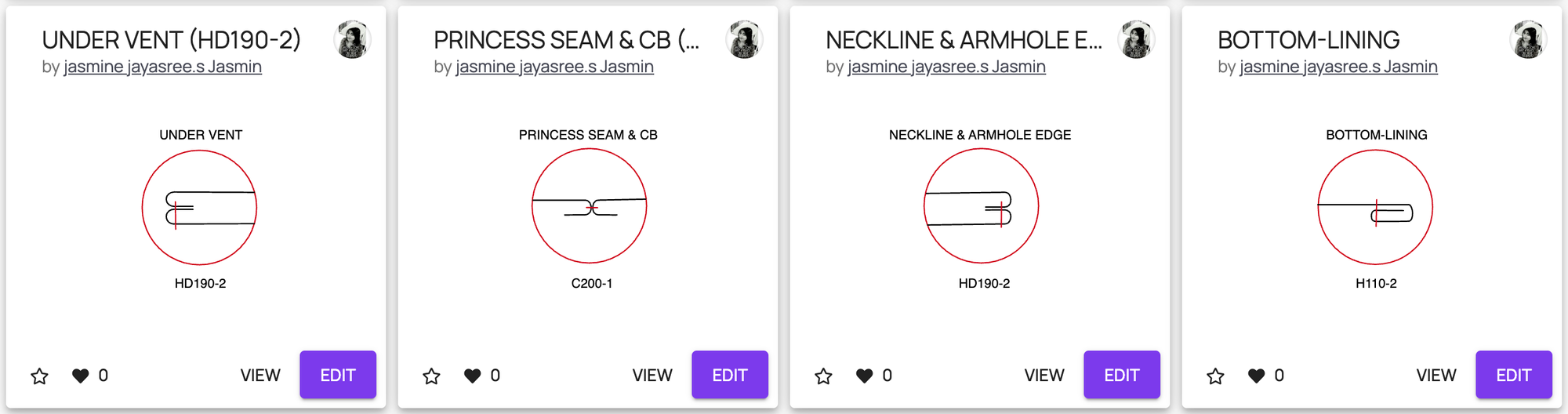

- A library of diagrams: Clear, visual, category-based seam drawings.

- Functional organization: Instead of jargon-heavy categorization, they group seams by purpose and use case.

- A code system: This removes naming inconsistencies.

- A communication bridge: Their entire system is made for both designers and manufacturers.

Belu explains how she arrived at the idea:

“I had been drawing my own seam diagrams for years because there was no simple code system to copy and paste. Manufacturers understood diagrams instantly, so communication was very fluid. When I moved to Australia and started teaching and freelancing, people began asking me for a catalog or a reference. That’s really how ABC Seams was born.”

Belu also clarified how ABC Seams differs from some older standards,

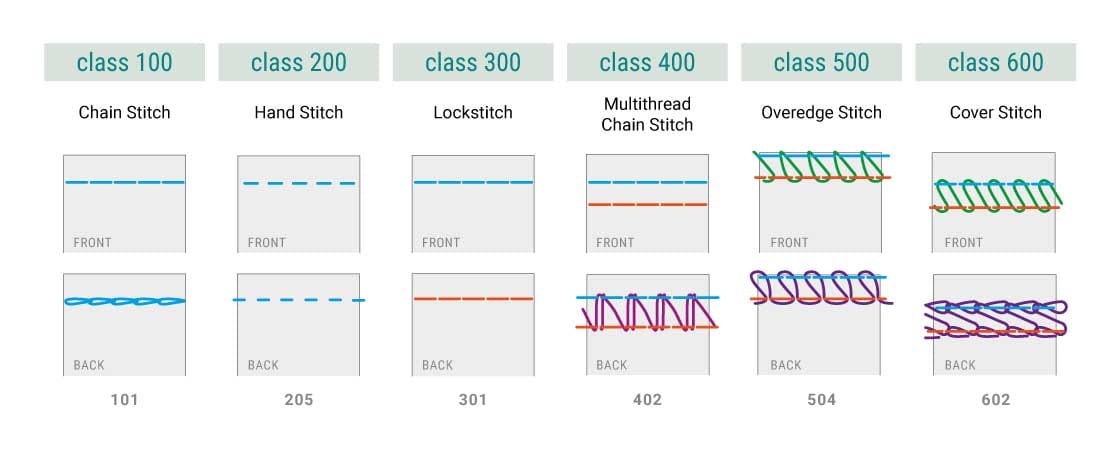

"Our system is quite similar, but the main difference is the approach to seams, and we are integrating the stitches and the different types of stitches - lock stitch, chain stitch, cover, the different type of cover, two needle, three needles. We incorporate all that in the same code system."

That extra detail helps remove ambiguity. I think this is the future. Not replacing creativity but protecting your intent.

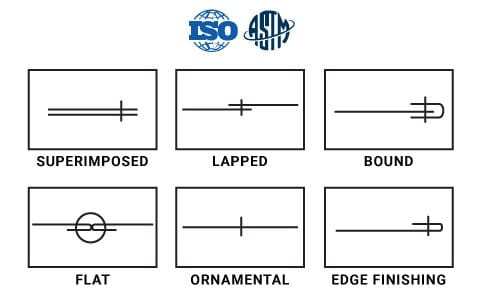

ISO & ASTM: The Structural Backbone of Seam Standards

When we talk about seam standardization at an industry level, two organizations form the technical foundation: ISO and ASTM. Most designers don’t reference them directly in daily work, but their standards quietly shape how seams are defined, tested, and validated across global supply chains.

The International Organization for Standardization (ISO) publishes widely used standards for textiles, stitches, and seams. These standards define seam classifications, terminology, and test methods that manufacturers, labs, and quality teams rely on for consistency across regions.

Why ISO matters

- Provides globally recognized definitions for stitch and seam types

- Helps align technical terminology across countries and suppliers

- Commonly referenced in industrial and technical apparel categories

At the same time, ISO was never designed as a designer-first communication tool. Its diagrams typically show how a seam is formed on a sewing machine, rather than how it appears inside a finished garment. That difference makes ISO technically accurate, but often difficult to use directly in tech packs.

As Belu explained during our conversation:

“The ISO seams, the approach that they have is that they represent the seam when you are stitching the seam, when you are sewing. So that is why it's been so confusing, and some designers use it, or developers, and others don't.”

In practice, ISO defines what a seam is, but not always how designers want it to look in the final product. Brands still need to translate these standards into garment-focused visuals.

ASTM International plays a complementary role, particularly in the United States. ASTM standards focus more heavily on testing methods, material specifications, and measurable performance outcomes.

Why ASTM matters

- Defines widely accepted tests for seam strength and seam slippage

- Supports durability and safety validation in workwear and technical apparel

- Useful when performance claims or certifications are involved

Like ISO, ASTM does not solve the designer-to-factory communication gap on its own. It validates outcomes and sets the performance bar, but it does not explain construction intent.

How they fit together

- ISO provides global technical definitions

- ASTM provides performance and testing validation

- Neither replaces visual, diagram-based seam communication in tech packs

Together, ISO and ASTM form the technical backbone of seam standards. Visual systems, seam libraries, and modern product development tools build on top of this foundation to make seam intent clear, consistent, and executable across factories.

Fashion Education & Technical Manuals

Before digital platforms and PLM systems, most of us learned seams through technical sewing manuals and fashion school textbooks. These books introduced the foundational logic behind seams, stitches and garment construction. If you went to fashion school, you probably remember pages filled with sketches of French seams, flat-felled seams, lapped seams and more.

These resources are still incredibly valuable today because they build intuition. They show you why a seam works, not just what it’s called.

Common references include:

- Reader’s Digest Complete Guide to Sewing (a classic with clear diagrams)

- Clothing Construction by Evelyn Mansfield

- Patternmaking for Fashion Design by Helen Joseph Armstrong

- University fashion curriculum manuals from FIT, Parsons, and NIFT (these often include simplified seam diagrams and construction breakdowns)

While these manuals are helpful, they share the same limitation Belu described when she compared older standards to ABC Seams.

Most educational diagrams show the seam in isolation, or the seam as it appears while sewing, not how it sits inside a finished garment. That makes them useful for learning, but sometimes harder to apply directly inside a tech pack.

As Belu explained in our conversation,

“designers, they don't usually sew. And some of them, they don't know the techniques.”

Her point is that even well-trained designers may not always connect these educational diagrams with factory-ready instructions. It’s one thing to understand a French seam. It’s another to specify it for a chiffon blouse with a 3 centimeter hem, a facing and a clean inside finish.

Fashion education manuals set the foundation, but they do not solve the communication gap between brands and factories. They’re a starting point, not a standardization system. That is where modern tools, diagrams and shared code systems begin to fill the gap.

Internal Brand Seam Libraries

Some of the most effective seam standardization I have seen happens inside brands themselves.

Teams build their own seam libraries with:

- Preferred stitch types

- Standard seam allowances

- Cross-section diagrams

- Brand-specific best practices

The problem is that these libraries often live in scattered folders or tribal knowledge. When senior staff leave, the “standard” leaves with them. This is why more structured, shared systems matter.

PLM Platforms & Product Development Systems

PLM systems do not standardize seams for you, but they are where standardization becomes useful at scale. Platforms like PLMBR, Centric PLM, PTC FlexPLM and Browzwear allow brands to build reusable construction components, attach diagrams to styles and share unified tech packs with vendors.

When brands embed seam libraries into PLM or tech pack tools, standardization becomes part of the workflow rather than an extra step.

A Practical Framework Any Brand Can Adopt

If you are thinking about standardizing seams in your own workflow, here is an easy place to begin:

- Categorize seams: Pick the top 20 seams your brand uses most.

- Attach a clear diagram: Create a clean diagram for each one.

- Assign a name or code: Assign a simple internal code or naming convention.

- Define default stitch logic: Add default stitch, SPI, needle and seam allowance.

- Build a shared library: Store these diagrams in a shared library in your PLM or tech pack tool.

- Train teams + vendors: Train your team and vendors on what each code means.

- Update document: Update the library quarterly based on factory feedback.

Belu reinforces this practical approach when she describes the benefit for small brands. She told us about an independent designer who struggled to find suppliers because his tech packs were not detailed. After using diagrams,

"He improved his results, but also, he's confident as a designer because he started to learn more. And once you start to use this type of technical language, visual language, you start to feel more confident because you see the results."

Toward a Broader Conversation on Standardization in Fashion

This blog is the first chapter in a new series we are building on standardization in fashion. Seams felt like the right place to begin because they touch every garment in every category, yet they are one of the least standardized aspects of our product development process.

In the upcoming posts, we plan to explore topics like:

- Color standardization

- Body form standardization

- Testing parameter standardization

If you want to follow along, I would love for you to join our newsletter.

We will be sharing real examples, resources, diagrams and interviews with people who are shaping the future of clarity in fashion.

Subscribe and be part of the Standardization Series. Let us build this knowledge base together.