Contents

3D fashion design technology is changing the way designers in the fashion industry approach product development, pattern making, and fittings. On the one hand, 3D clothing design software simplifies the design development process, saving time and money while reducing environmental impact. While on the other hand, 3D and augmented reality experiences enable fashion brands to connect with audiences all over the world, resulting in stronger brand affinity.

With the advent of virtual clothing, fashion designers no longer need to use real fabrics or sew by hand. This has transformed the way clothing is made and manufactured.

What is 3D fashion design?

3D in fashion design is the process of developing a 3D prototype out of a 2D digital pattern. With the help of 3D technology, designers can now build a 3D garment directly on a digital avatar (model) of their size.

3D digital design helps brands design and sample clothing more quickly and with less waste. 3D technology can display ultrarealistic images of a garment, including the fabric drape and appearance.

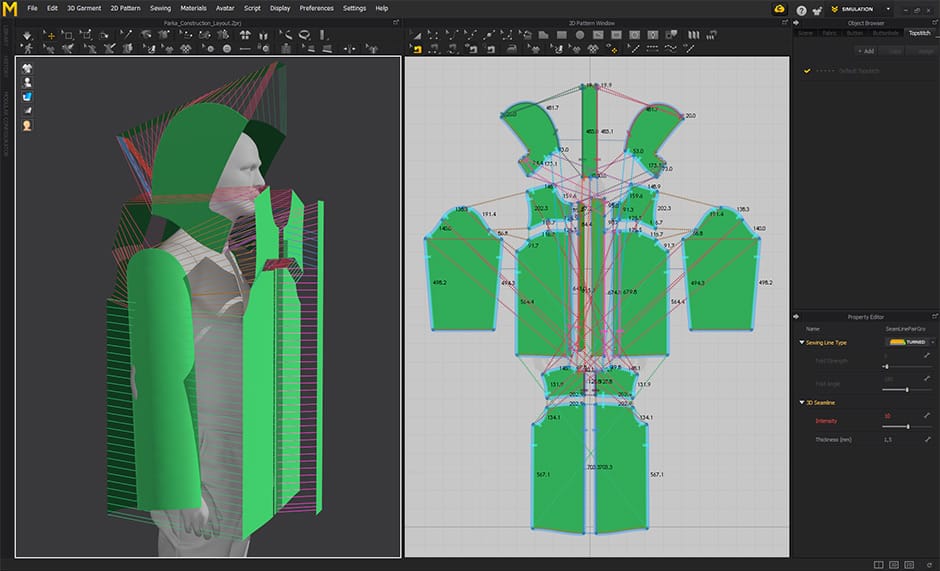

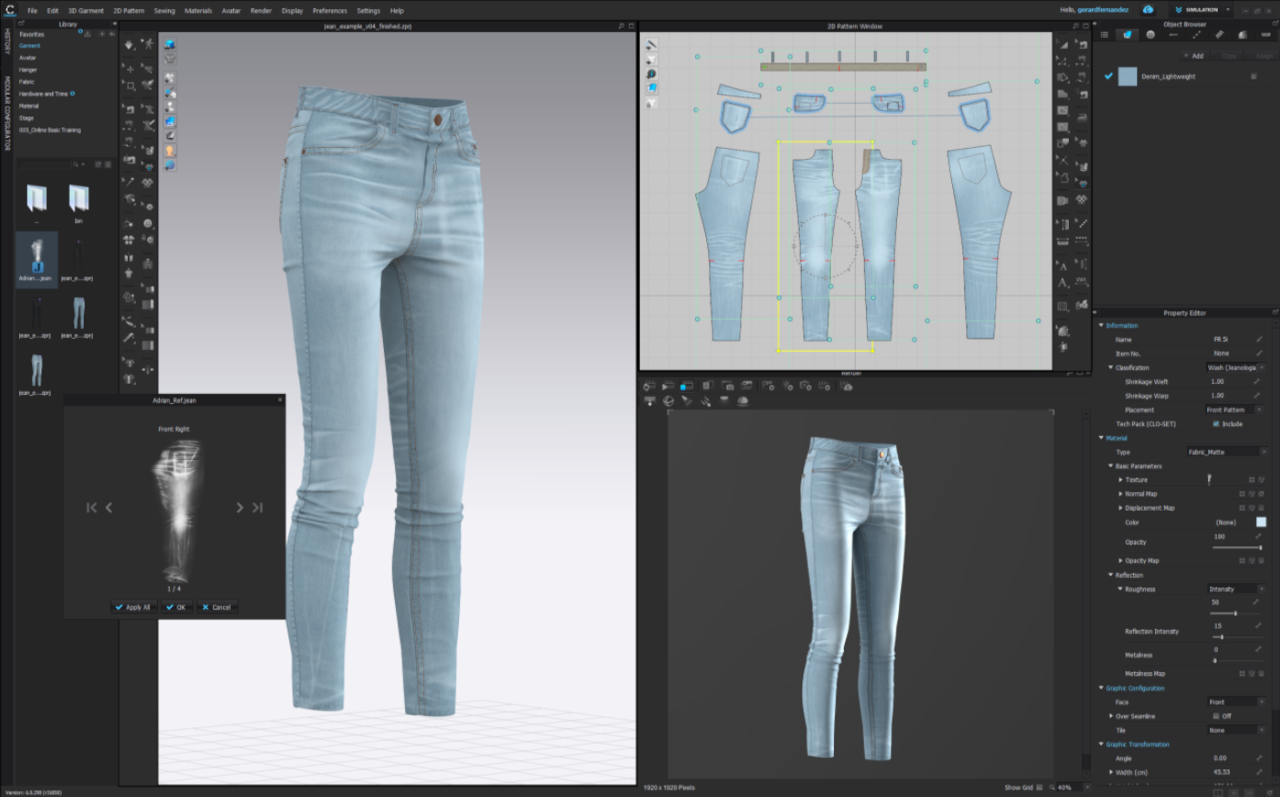

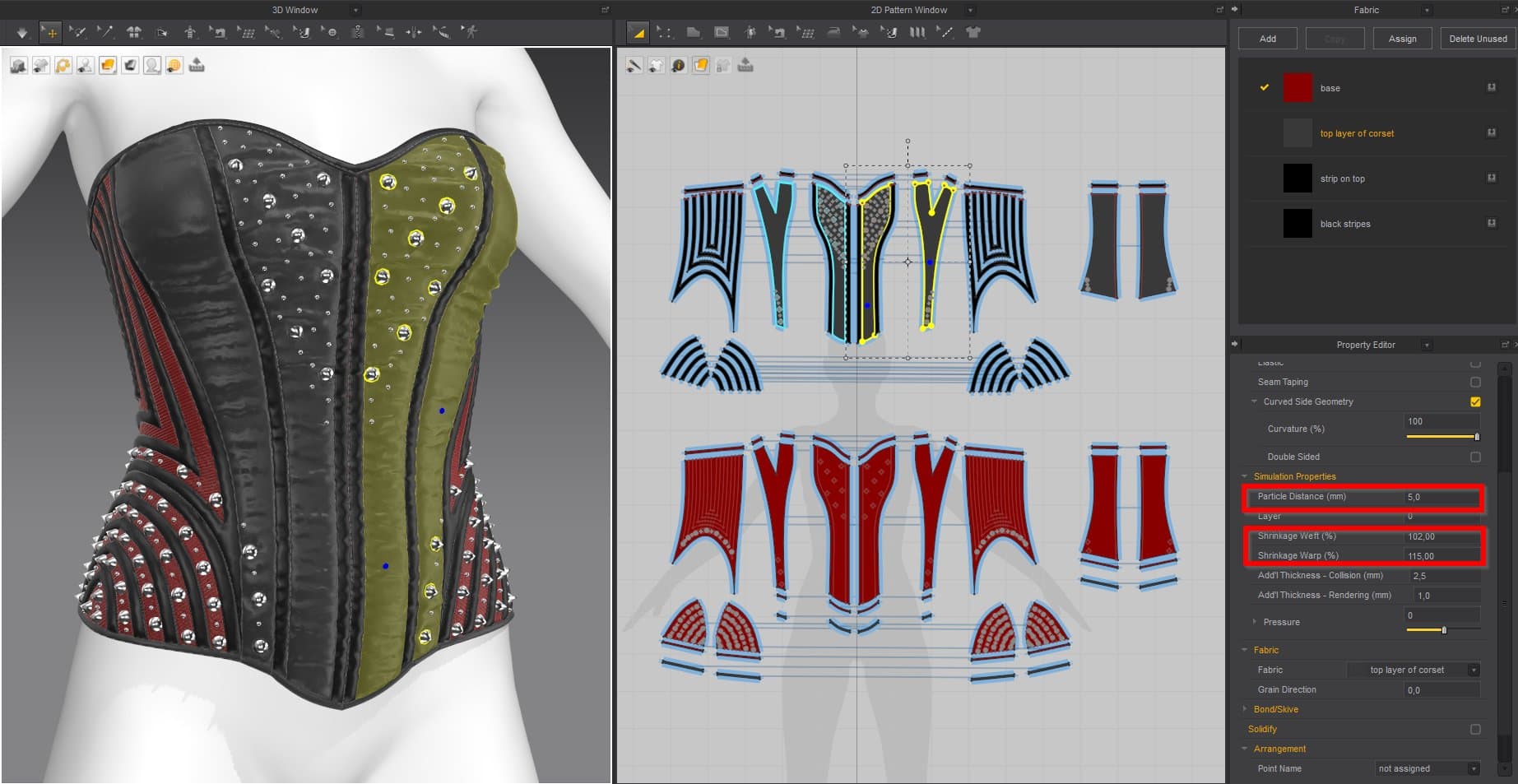

Instead of working with 2D patterns and files, fashion designers are using 3D software to stitch patterns together and provide a production-ready 3D version of a garment.

The benefits of 3D fashion design

Adidas, Hugo Boss, Louis Vuitton, and even small fashion companies are incorporating 3D solutions into their design workflow.

The benefits that 3D design tools can provide to apparel companies are substantial:

It speeds up your production

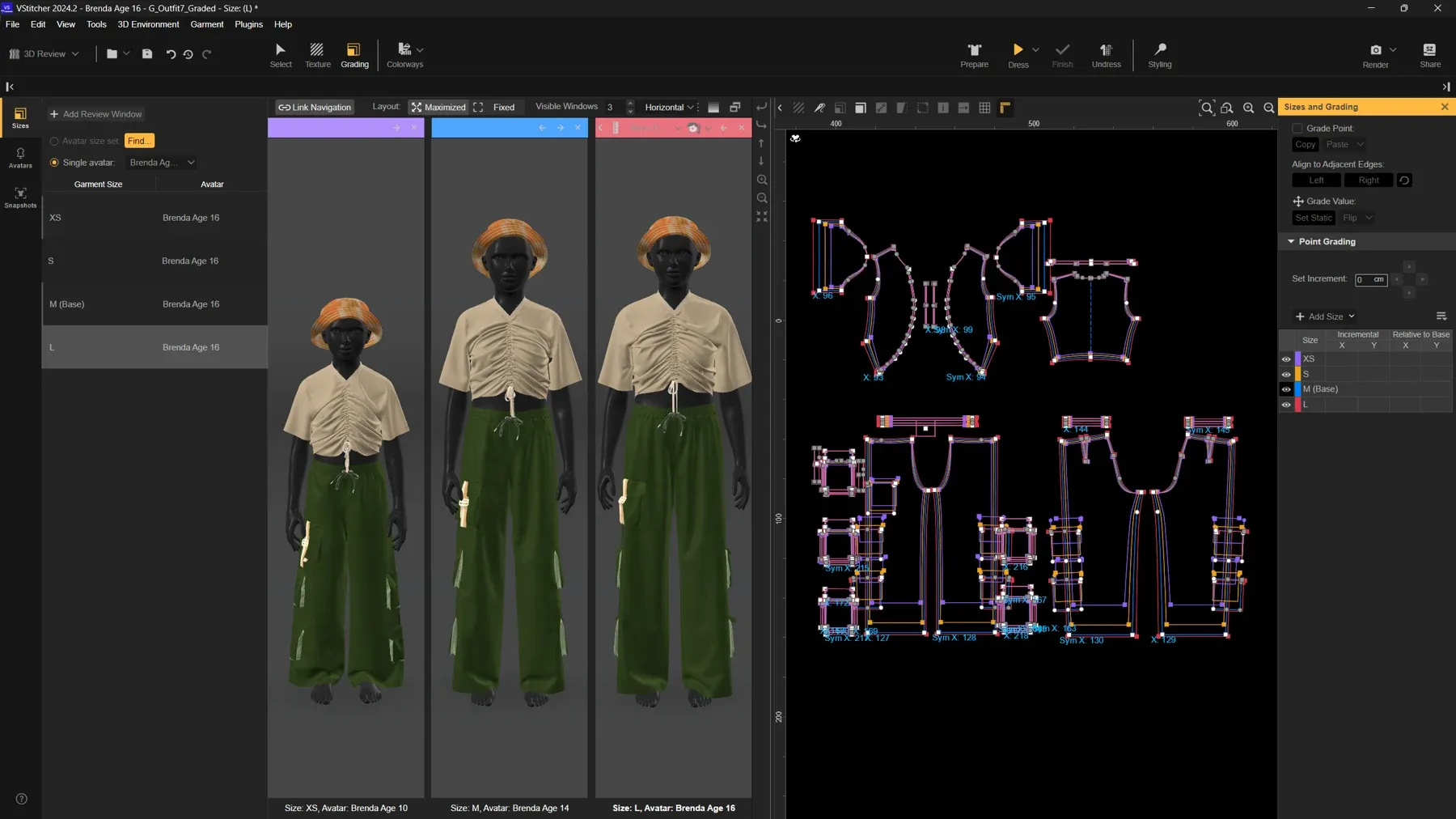

One of the most important advantages is that they help increase overall production speed. Designers can perform many virtual iterations of a garment, potentially shortening the product's time to market by weeks or months. If you make a mistake during the design process, you can easily edit your patterns. If you're making symmetrical garments, virtual design tools have a number of time-saving features that can sync together patterns for either the left and right sides or the front and back of the design.

It lowers sample-making costs

3D technology reduces sample-making costs significantly. Brands can create and share photorealistic garment visuals without making a physical sample.

It helps reduce waste

Another benefit is that the 3D process addresses the sustainability issue by drastically reducing waste associated with many rounds of sample sewing. Working in 3D is simply the most ethical and sustainable way to design clothing. You can create your collection in 3D, hold virtual fittings in 3D, and even release it virtually.

It ensures a better fit

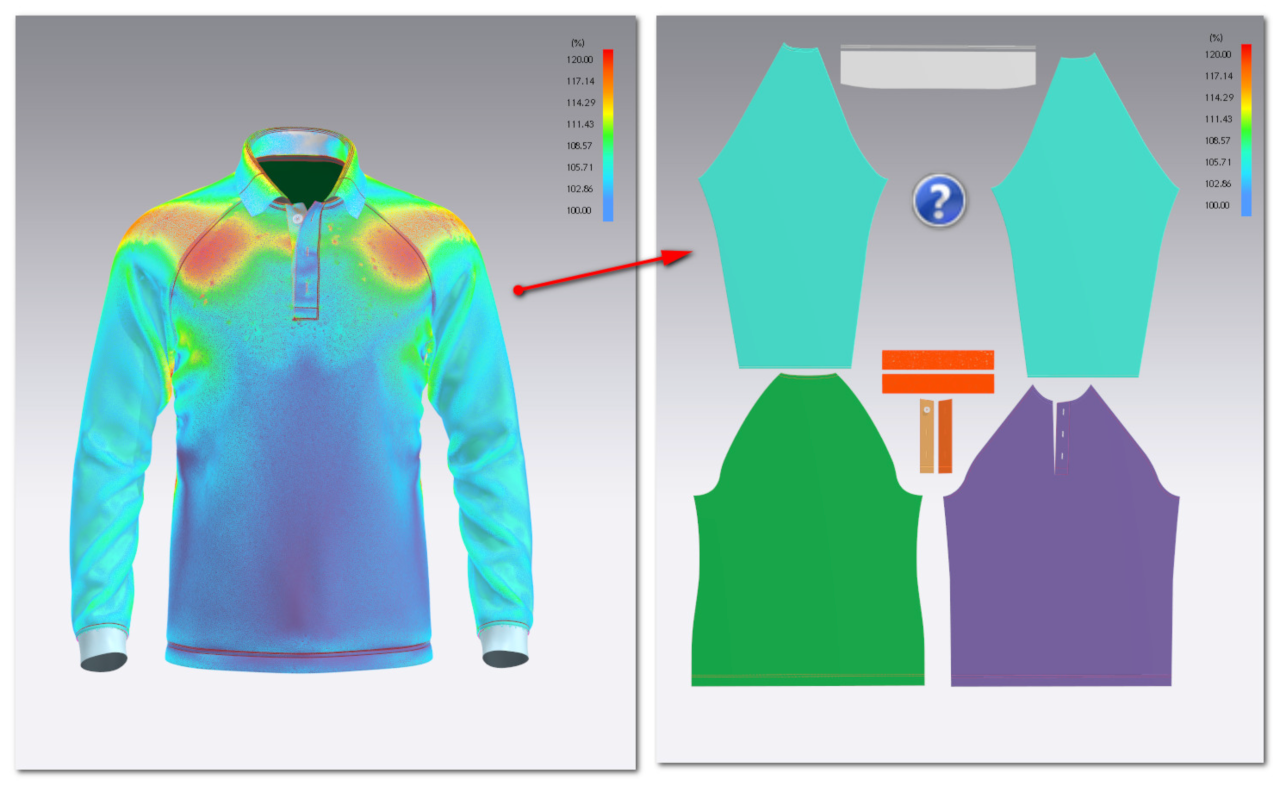

3D technology allows you to test the fit of your garments before sending them to production. With the help of stress maps, you can easily see the problem areas and quickly adjust them.

You can pre-sell your clothing before it is produced

You can create an entire collection with the help of 3D technology and showcase it on your website. Create a variety of sizes to show your customers how they will fit on them.

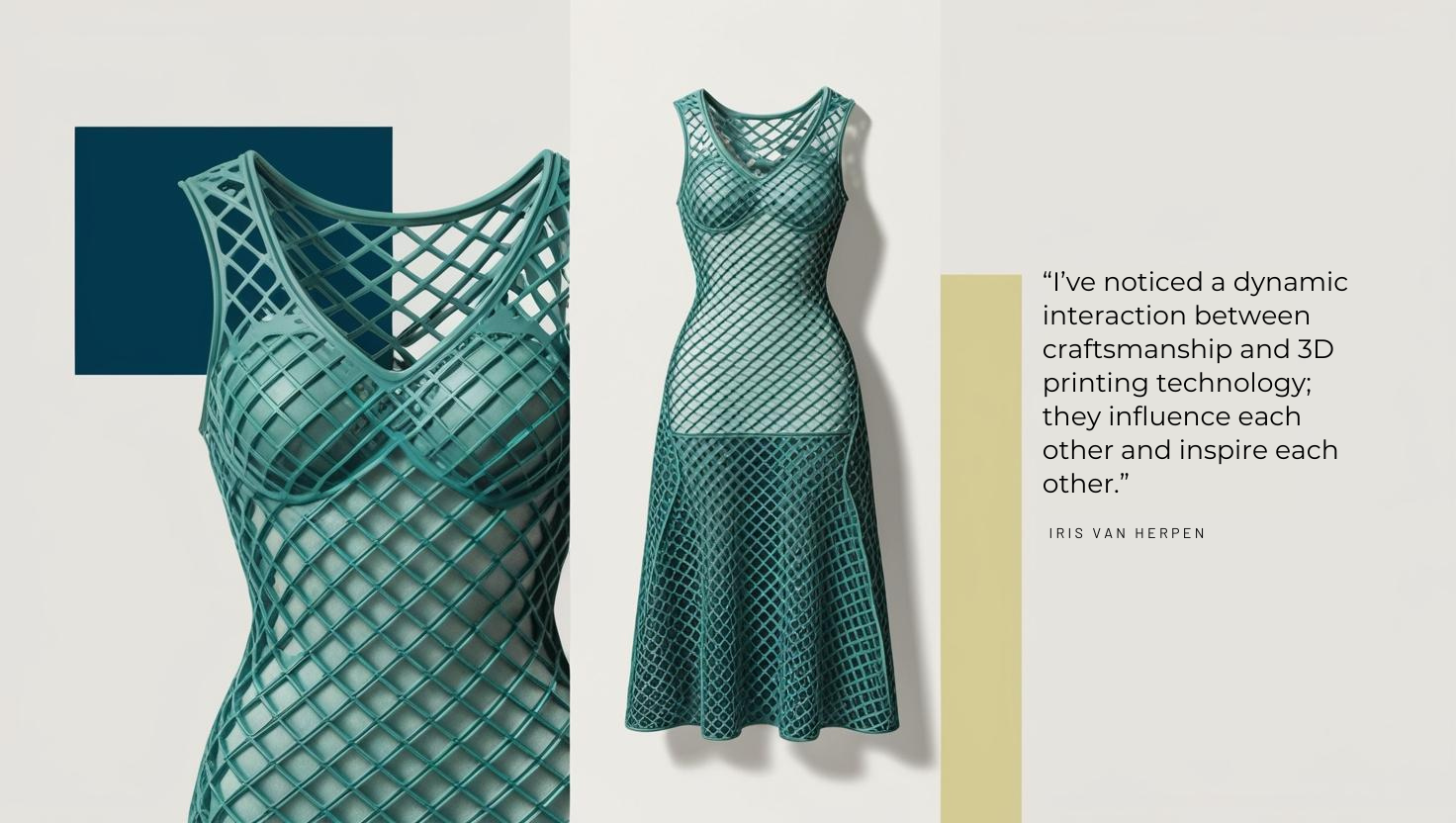

You can create clothing using 3D printer

Shopping customers can create personalized ensembles using 3D models of clothing. With the use of 3D clothing modeling, customers can style their own clothing to create unique looks. A 3D printer may be used to create actual clothing and accessories using 3D fashion.

Read more in-depth about 3D printing technologies and their application

You can conduct virtual fashion shows

The ability of 3D clothing models to simulate any environment and enable user interaction is their main strength. Designers may then be able to take customers somewhere that fits the theme of the apparel or accessories on offer.

How to create a 3D garment?

To create a 3D garment, you will need to make a 3D avatar (model) first. The creator has complete control over the figure's parameters (height, waist, and chest circumference). For instance, avatars with pre-set parameters specific to this sport are employed while designing clothing for athletes.

Then, you will start drafting the 2D pattern. Many 3D fashion design solutions also allow you to import digital patterns into their systems.

Then the pattern pieces are sewn together and fitted onto the avatar. From there, you can add the fabric properties, stitch types, and adjust the fit of the garment with the help of stress maps.

In order to assess how the clothing would behave in real life, the designer builds a product using the components and replicates the actions of the 3D model fashion avatar (dancing, sprinting up the catwalk, etc.). Unloading patterns for later transfer to production are a crucial element.

Which 3D software is best for fashion design?

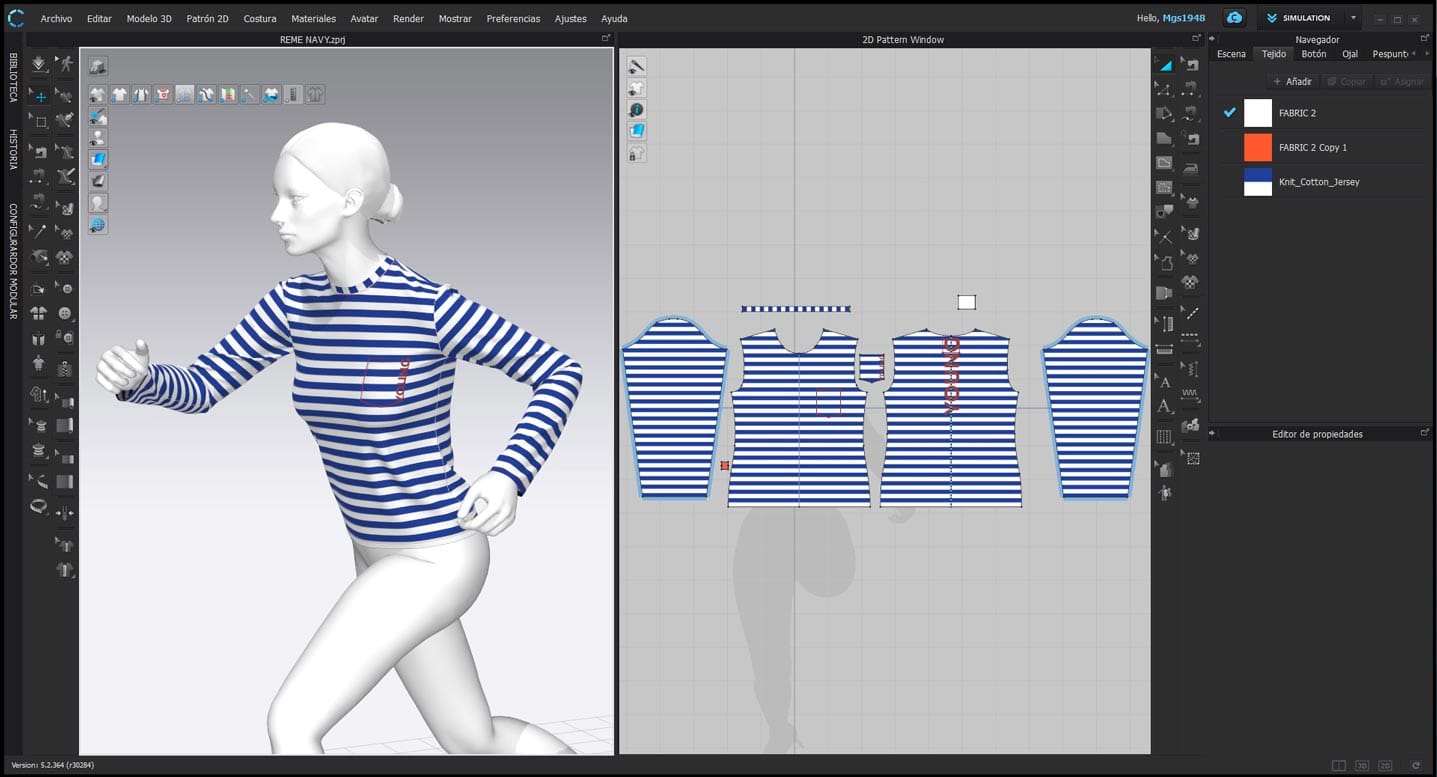

CLO 3D

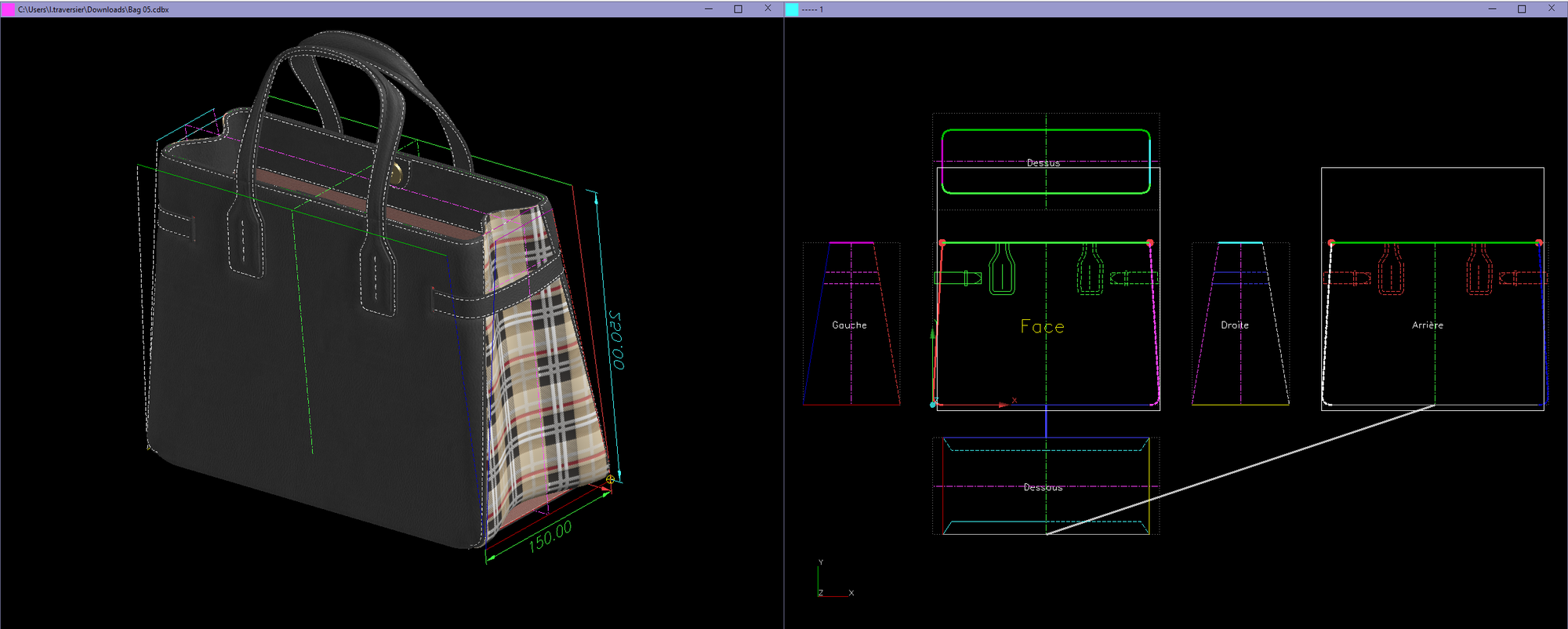

CLO 3D is design software that allows you to get 3D renderings from 2D patterns. It is a great tool to get a visualization of the products, check the fit, and test different fabric and color options. It also allows you to export patterns in multiple formats. CLO 3D platform has an intuitive interface and provides a lot of video tutorials to its users.

Marvelous Designer

Marvelous Designer is a cloth simulation program that is used to create dynamic 3D clothing for games, films, 3D art, and 3D animations. This software is compatible with a wide range of other 3D software like 3DS Max, Maya, and ZBrush, making it even simpler to edit your 3D model.

TUKA 3D

Tuka3D is a user-friendly 3D fashion design software created by Tukatech. This software allows you to scan your fit model and adjust it using the various measurement options available. Create a virtual fitting session with an animated model who can move, dance, run, and so on. This 3D software is specifically designed for virtual prototyping, allowing you to conduct numerous trials for a single product.

Browzwear

Browzwear is a 3D fashion design, development, and merchandising solution. Browzwear provides several modules. VStitcher, a 3D virtual prototyping solution for technical designers and pattern makers. With its help, you can convert 2D patterns into 3D models. Lotta, a 3D fashion design solution that helps fashion designers develop clothing. You can easily synchronize your 2D drawings and patterns with Lotta using Adobe tools such as Photoshop or Illustrator.

Romans CAD

Romans CAD is a software specifically designed for the footwear and leather goods industries. Romans CAD enables designers to make all of the required changes to your products with great accuracy. This is a powerful cloud-based program designed to increase productivity and improve communication between designers and manufacturers.

Sign up for our FREE membership and get access to

All premium articles

E-courses and ebooks

Ad-free experience

Tech pack templates

3D virtual fitting technology

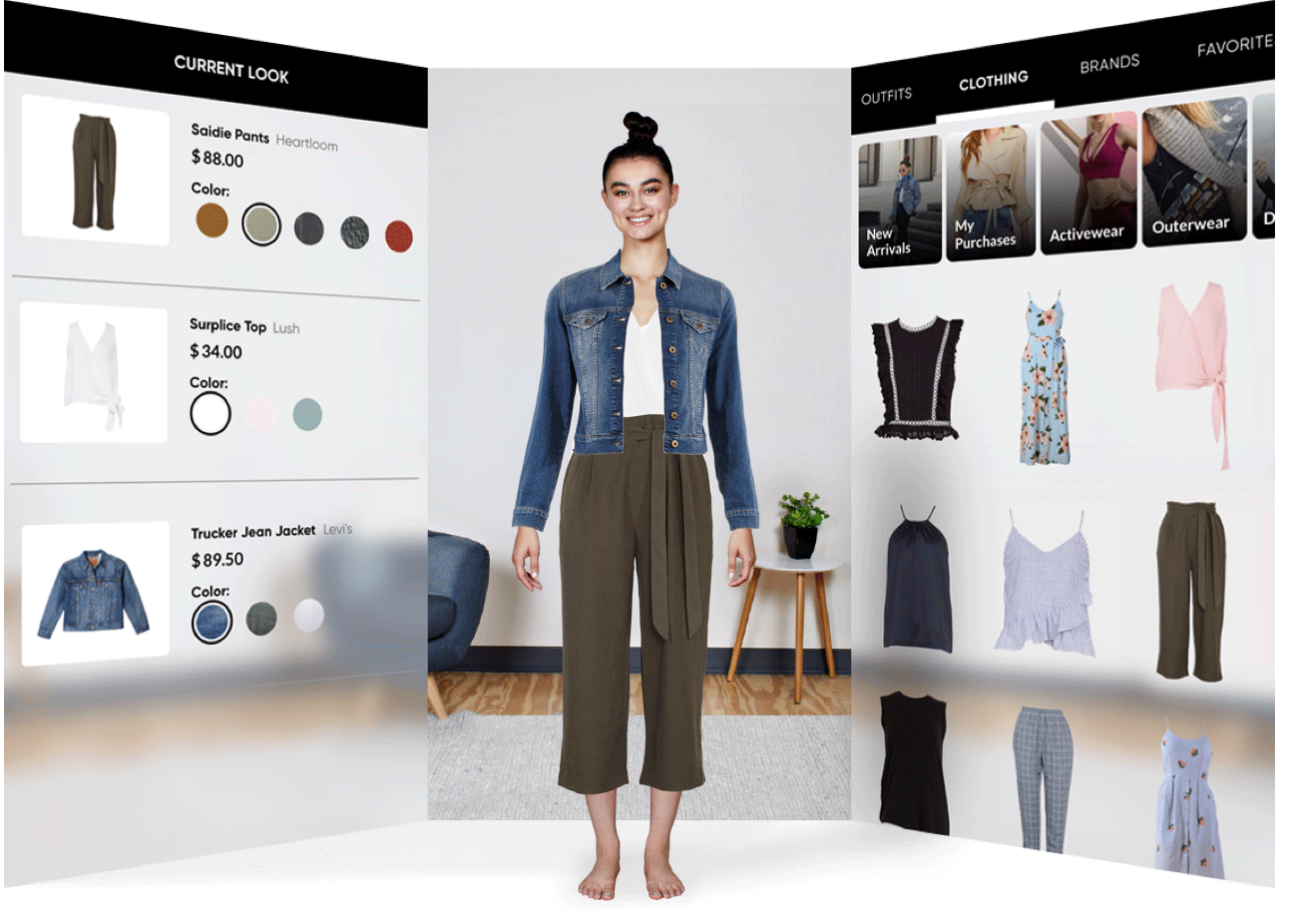

Another way to utilize 3D technology in the fashion industry is by taking advantage of 3D virtual fitting technology.

With a rising number of returns and landfill waste, fashion desperately needs technologies that will help to address the issue of poor fit.

Many fashion companies, like Macy's and ASOS, and luxury brands like Louis Vuitton and Dior, are already exploring the potential of AR clothing try-on technology in the fashion retail space. Their virtual fitting solutions allow consumers to preview garments on their own bodies, whether they're at home or in-store.

Virtual fitting rooms allow consumers to try on the garments without physically wearing them. To implement 3D virtual fitting technology, fashion brands use their customers' body data. The AR technology maps a virtual version of a product to the customer’s body on top of a realistic 3D avatar using a camera-equipped device.

There are certain challenges that fashion brands may face while utilizing virtual fitting solutions. First of all, the implementation costs. The other challenge is data privacy concerns among consumers. Mobile body scanning, visual fitting rooms, and virtual try-on technology all face the additional challenge of storing consumer data such as names, addresses, banking information, and biometric data. To allay consumer fears, solutions must be designed with privacy in mind, and companies must provide transparency and security when storing customer data.

Beyond these challenges, 3D virtual fitting technology has enormous potential to improve the way fashion is designed, sold, and consumed. By reducing the number of physical samples that end up in landfills or creating a virtual fitting room for e-commerce that can reduce return rates.

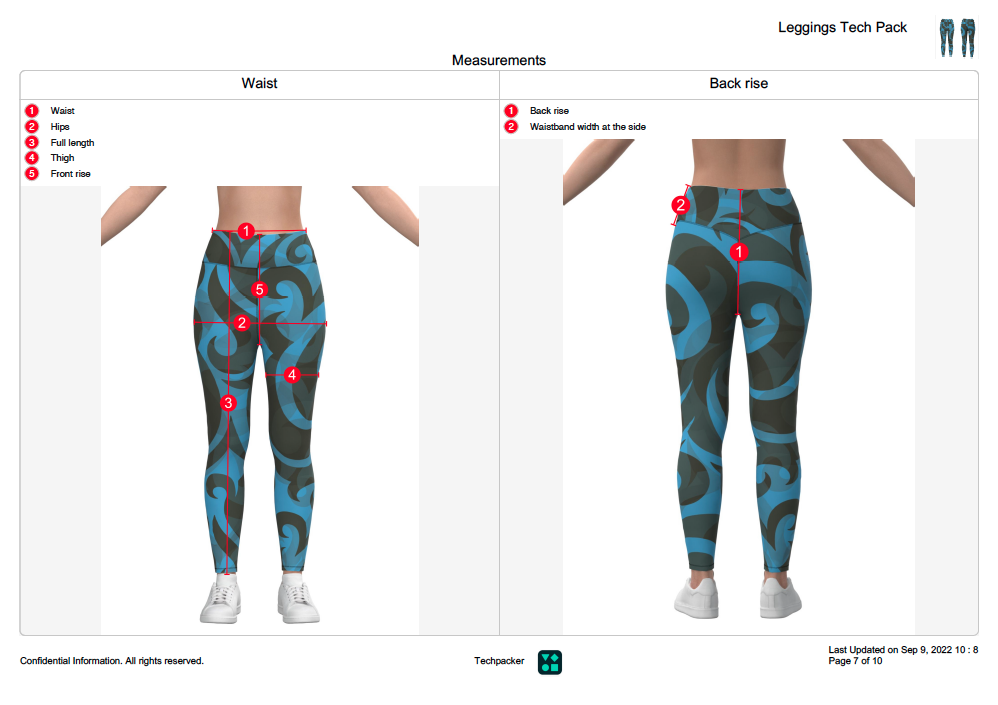

BONUS: Tech Pack made with 3D fashion design

Use our free activewear- leggings tech pack as a base to design your own style or as a reference guide.