Contents

As technology continues to advance at an unprecedented pace, the manufacturing industry is experiencing changes akin to the Industrial Revolution of the 1800s.

Fashion production manufacturing, in particular, has seen remarkable innovations that are transforming the industry as we know it. To meet the demands of delivering the right products to the right customers at the right time and price, manufacturing processes are evolving rapidly through digitization and connectivity.

The rise of the internet and hyperconnected consumers has raised expectations, prompting brands and entrepreneurs to gather data faster and more efficiently, adapt to customer feedback, and address supply chain issues promptly. This shift is reshaping the fashion cycle, requiring businesses to be more agile and responsive.

While numerous trends are shaping the future of manufacturing, nine key factors are currently exerting the most significant influence and generating new components.

The rise of machine learning

A machine’s ability to learn and adopt intelligent human behavior is not new. Today, these advanced algorithms are transforming the way the manufacturing industry collects information, performs skilled labor, and predicts consumer behavior. Some even predict themes in trending patterns, silhouettes, colors, and styles and provide customer sentiment around products and runway images. Some are almost taking the place of humans to detect when it’s the right time and product for a brand’s ideal customer.

Tommy Hilfiger, for example, announced a partnership with IBM and the Fashion Institute of Technology to develop an Artificial Intelligence System to determine this kind of data to optimize production, and sales and also reduce cost and waste. The students at FIT will have IBM Research’s AI capabilities including computer vision to look into the company’s data like real-time fashion industry trends, and customer sentiment around every Tommy Hilfiger sent back to the student designers to make informed decisions for new product development.

Another company San Francisco-based, Stitch Fix which delivers clothing to customers with the help of online stylists, is also working with AI. They are now designing garments created by algorithms that identify trends and styles missing from the Stitch Fix inventory. These are based on combinations of consumers’ selections of favorite colors, patterns, and textiles which are picked by the AI system which then suggests a new design. Then these new designs are reviewed by a (human) design team.

Supply-chain optimization

As people become increasingly “impatient” shortening lead times is key to ensure delivery with optimum timing. This is why many companies have taken a step further and are the entire process “in-house” to increase speed and supply chain efficiency. Things like materials sourcing, creative and technical design, samples, production, and shipping under the same roof. And for everything to run smoothly all the teams must have a real-time flow of information to ensure everyone has access to the same data and the same version of the latest products.

This "in-house" production thinking is already being implemented by many companies, from big brands like Gucci to small manufacturers like Suuchi Ramesh.

The first decided to internalize part of its production to speed up the pace of manufacturing and meet consumer demand quickly. The second has become famous thanks to the innovative in-house production approach which handles handling fabric sourcing, product design, manufacturing, and sales under one roof.

Suuchi Inc. currently uses 100 different machines that enable 30% to 40% of the clothing production to be automated.

"Our effort is to reduce manual intervention and eventually introduce robotic technology and automation," Ramesh said to CNN.

Sign up for our FREE membership and get access to

All premium articles

E-courses and ebooks

Ad-free experience

Tech pack templates

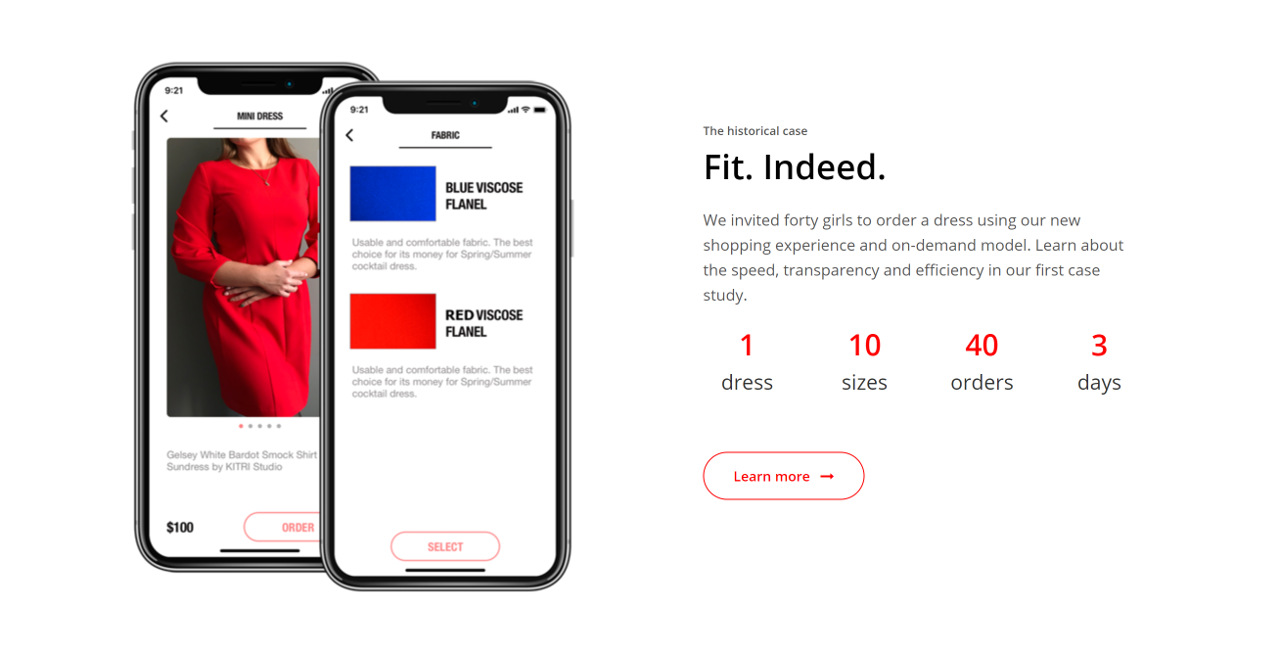

Fashion on demand

Fashion on demand is a new trend to watch. New technologies like automation and data analytics are shifting consumer needs to just-in-time production. Many brands are switching to made-to-order production cycles. The result is a reduced level of overstock and less clothing that ends in landfills. Lately, we’ve noticed an increase in the importance of the small-batch production cycles.

Typically, a production cycle was a long time-consuming process requiring nearly a year of planning. New technologies and analytics are becoming a solution for brands to quickly source and develop products, shorten production timelines, and streamline distribution.

New fashion brands are the first to adopt the new made-to-order trends. Like Parisian brand Dressarte which offers 100% customized sustainable clothing.

New York-based software company ShareCloth contributes to the on-demand brand by digitizing styles. They create 3D samples of garments and 3D virtual bodies of the customers enabling retailers to place orders before manufacturing the products.

Some of the big players are also stepping up. Big companies like Boohoo, Zara, Uniqlo, and Asos are embracing the model.

Large brands like Prabal Gurung require 8 to 12 weeks for their made-to-order line. So the team can dedicate their resources for the team to dedicate their resources like design, production, pattern-making, and customer service.

There are positives and negatives to on-demand production from an economic point of view. On-demand production requires lower capital investment which leads to a small batch inventory and a more sustainable production cycle. However, due to the lower quantities of garments produced the manufacturing costs are higher.

Robot designs for the manufacturing floor

Robots have traditionally been ideal to perform tedious, repetitive tasks on the assembly lines in factories. However, the latest advancements have equipped robots with memory and agility making them highly programmable and collaborative. It is not about eliminating positions, but about making smarter workers, and also keeping humans safe by replacing them in dangerous situations where robots can do the job.

Of course, robots in fashion manufacturing have not come without challenges. For example, cutting fabrics with robotics has been possible for years, but sewing has been more difficult as robots are not ideal for certain textiles like pliable or elastics for example.

Some companies like SoftWear Automation have developed “Sewbots” equipped with robotic arms and vacuum grippers, that can guide a piece of cloth through a sewing machine very accurately, bringing down costs and speeding up the process.

Just two years ago robotics startup Sewbo launched a robot capable of sewing a t-shirt without any human intervention using water-soluble stiffening solutions to turn cloth into cardboard-like material.

For their part, since 2013 Nike has been manufacturing shoes under Grabit a robotics startup that uses electro adhesion to help machines manipulate objects.

Digital factories

As companies implement innovative technologies, digital factories are transforming clothing manufacturing. Leading manufacturing companies are digitizing their production and supply chains. They deploy key technologies including big data analytics, end-to-end, real-time planning, autonomous systems, and worker augmentation. These technologies allow companies to produce highly customized products and gain significant efficiency.

Factories of the future will be completely automated with self-repairing and self-servicing structures. Requiring minimal human intervention. They will allow predictive analytics and self-diagnostics. With the help of real-time processing and data analysis, fully integrated smart factories will provide a highly accurate overview of all stages of the manufacturing process.

One of the strategic methods of digitalization is the digital twin approach. With digital twins manufacturing processes can be replicated on a digital platform within a virtualized environment. Digital twins can be used to test out new process solutions for the factories, without the expensive overhead. In the long run, that can minimize the production costs.

Get a full insight into the clothing manufacturing process in this guide

Rapid data analysis for quick adaptation

Thanks to the Internet and new software brands and factories can receive real-time feedback and alert companies of defects or damaged goods helping them save money and eliminate waste, helping deliver adequate products at the perfect time.

Some opt for management software like IQMS which serves in manufacturing monitoring and data collection of your production in real-time as parts are being made and applied to the shop orders.

Today as cloud computing has grown, it lets factories and companies work together from many parts of the world at the same time. This can allow them to access relevant data, facilitating quicker, more productive, and clearer communication.

Legacy enterprise resource planning (ERP) systems in manufacturing are being replaced by Cloud-based systems. Those systems enable automated updating without the pitfalls of downtime and can manage whole-system solutions.

The manufacturer can keep their financial, warehouse, and client information safely in one platform. Software-as-a-service (SaaS) companies offer increased versatility and flexibility to adapt to fluctuations within markets. That potentially can eliminate the overhead costs of running an in-house IT department. It also allows better visibility of the entire supply chain.

In clothing manufacturing adoption of cloud-based is expected to grow more in the coming years. Offering transparency in the entire supply chain and potentially helping to reduce production costs by eliminating unnecessary spending whenever possible.

Some labels like Badgley Mischka are already collecting data as soon as the models step on the runway showing the latest designs. Thanks to a mobile application they developed for iOs the label solicits feedback from the fashion show attendees to gain more insight on how customers are reacting to an outfit. This information is transmitted to retailers that carry their lines, helping with custom forecasting, replenishment of stock, and optimizing business planning.

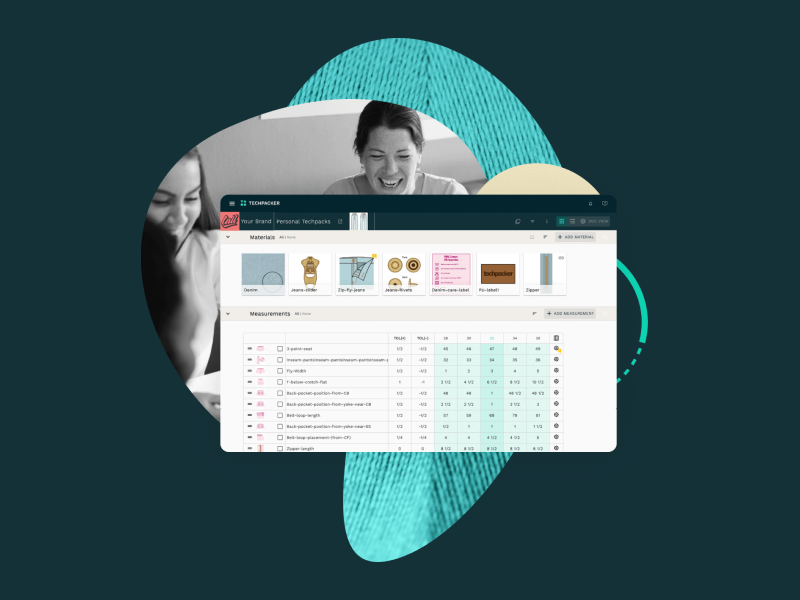

Manufacturing CRM

Manufacturers are adopting new processes for managing customer relationships and improving product sales all in one place. The type of software, known as manufacturing CRM allows manufacturers to organize customer data, and close deals more quickly all in one platform. It allows manufacturing businesses to get insights into customers' needs that can be used to improve existing products and help develop new ones.

Techpacker makes it easy for factories to track product development and communicate with clients online. It allows manufacturers to receive tech packs with high-quality images, translate files to destination languages, and easily track clients' tech pack changes.

3D Design, printing, and mass customization

Elsewhere, brands are exploring how 3D printing can help them produce goods on-demand and create new avenues for customization. This has become an increasing need as competitiveness lies more and more in delivering products tailored to the customer's tastes and needs in a speedy and timely manner.

There are new 3D rendering technologies like CLO which allows brands to edit designs at the moment and instantly review changes. This can help improve the quality of designs by checking silhouette and fit sooner in the development process minimizing unnecessary waste, and error in the sample before finalization.

Another one is EFI Optitex which greatly improves the expensive and lengthy process of finding an adequate fit by taking essential components of the designs like flat sketches and technical patterns which morphed into simulated 3D renderings, which allows cutting, loosening the fit, and making all necessary adjustments in real-time.

Also, 3D printing has been huge for on-demand production. From Adidas’ 3D printed shoes to apparel brand Ministry of Supply, which uses an in-store 3D printer that creates customized knitwear on the spot. In addition, printing garments on demand reduces fabric waste by about 35%.

Digital knitting is also changing the apparel industry, making great strides. It is not only showing incredible advancements in the 3D printing sector but offering another entire range of customization possibilities. For example, brands like Australia-based fashion label, Shima Seiki can turn cones of yarn into a full, seamless garment in less than one hour, while Ze-Nit is creating digitally knitted urban wear allowing for functionalities and benefits to be placed where the body needs it most.

Green Manufacturing

The global focus on sustainability has driven the fashion sector to adopt green manufacturing processes, stressing ecologically responsible production methods. Today, green manufacturing is about more than just lowering carbon footprints; it is also about increasing efficiency, eliminating waste, and rethinking established production processes.

Stella McCartney, a leading brand in sustainable fashion, is one such example. Stella McCartney uses environmentally friendly materials such as organic cotton, regenerated cashmere, and bio-based alternatives. In addition, the brand's devotion to closed-loop operations guarantees that waste is minimized during production.

Patagonia is another significant player that has used new approaches such as recycled polyester manufactured from plastic bottles and worn-out clothes. Patagonia's dedication to renewable energy and ethical labor practices exemplifies a comprehensive manufacturing sustainability strategy.

Lenzing Group, well-known for its TENCEL™ fibers, is promoting green manufacturing practices. The company uses a closed-loop technique to generate fibers from sustainably sourced wood, resulting in minimal environmental effect. Their process recycles water and solvents, which dramatically reduces waste.

Furthermore, technological breakthroughs such as renewable energy-powered factories and waterless dyeing methods are gaining popularity. Dyecoo, a Dutch firm, has invented a water-free dyeing method that uses CO₂ instead of water, reducing the need for toxic chemicals.

Green manufacturing meets consumer demand for transparency and environmentally conscientious processes. As brands and manufacturers continue to innovate, the sector gets closer to a sustainable future in which prosperity and environmental responsibility coexist.

To get fresh industry updates and original content in your inbox every week, sign up for the Techpacker weekly newsletter! no spam, only carefully curated news!