Contents

The COVID-19 pandemic has brought the issues of the fashion industry into sharp relief. The pandemic has affected everything from product design to the supply chain, leaving many brands with both financial and material concerns. The key problem the pandemic has initiated is that the wholesale model no longer works. Too much stock has been produced and there is a lack of retail footfall, in physical brick-and-mortar stores, to allow this stock to be sold. This has also had severe financial implications. In March 2020, clothing sales dropped as consumers were no longer able to purchase in retail stores.

The Impact of COVID-19

There are also broader, and longer-term, implications of the pandemic which may shape the fashion industry for years to come. COVID-19 has instigated a period of working from home that has left many designers away from their usual, collaborative environments. The global nature of the fashion industry has been deeply affected by regional lockdowns globally. Supply chains have been interrupted everywhere between China to Brazil, Italy to England. With the uncertainty of the pandemic, getting used to the ‘new normal’ is something the industry must do to survive. There are also the ethical considerations of the pandemic. Many factories in developing countries are facing economic ruin; affecting the lives of thousands upon thousands of seasonal garment workers. However, in the face of the tragedy and struggle of the pandemic, the fashion industry has begun to adapt its supply chain to foster changes that may ensure its very survival.

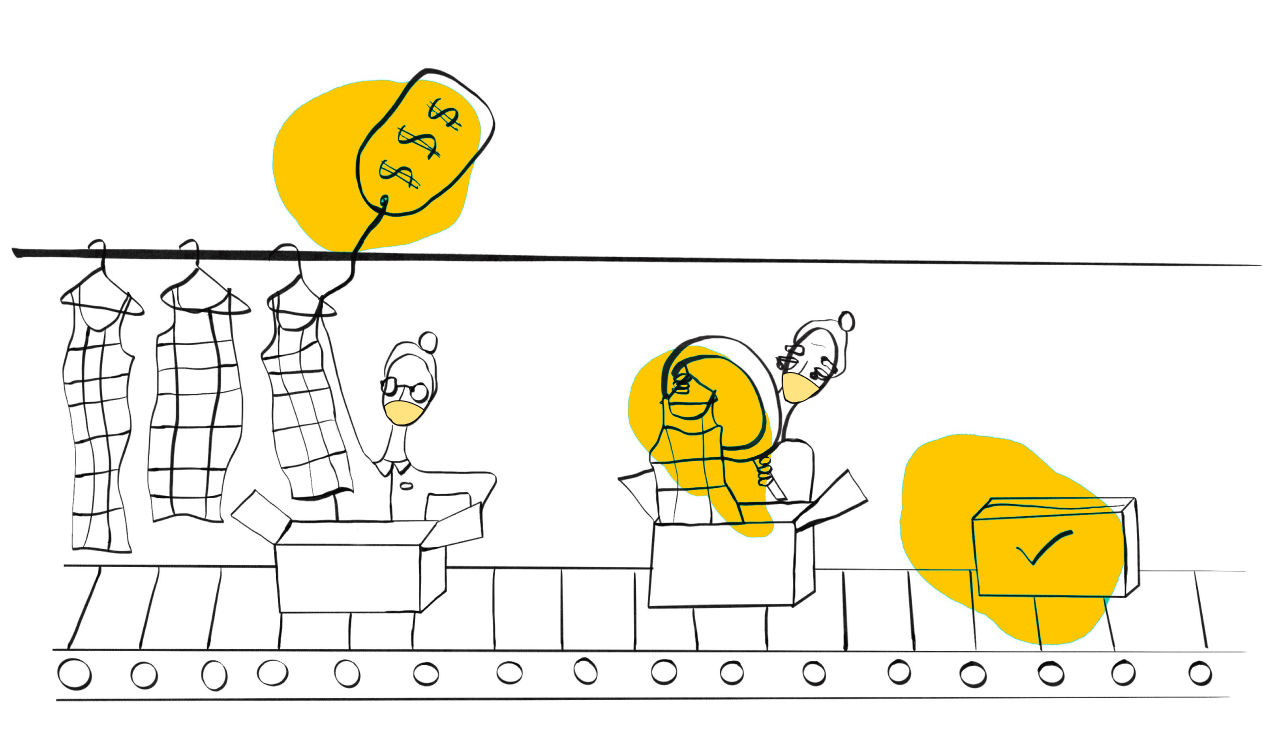

A new production model for the supply chain

A number of top fashion magazines, including Elle and Vogue, have argued that made-to-order fashion appears to be a solution to these supply chain concerns. Made to Order, or on-demand, fashion is where designers order the manufacture of their designs on a demand basis. Here, instead of buying the bulk of stock for consumers to view before purchase, the stock is not actually made until after it has been ordered. Techpacker has covered everything you need to know about made-to-order fashion in a recent blog post, which can be found here.

It’s not just fashion news that believes made to order is the future of fashion. Consultancy firm McKinsey have released a detailed report that argues fashion retailers must reform their product development process to survive in the pot-COVID age. A survey conducted by the firm found that “76 percent of the international sourcing community believe that the COVID-19 crisis will accelerate flexibility and speed over the next year. Of these respondents, 52 percent expect to see a high acceleration of more flexible product development with shorter lead times and smaller batch sizes.” Arguably, using a made-to-order model helps to refocus business to e-commerce, which does not rely on physical stores being open to sell products.

Made-to-order also helps to mitigate some of the ethical concerns surrounding the pandemic. According to Forbes, sustainability is something consumers are urgently looking for. Online searches for sustainable fashion tripled between 2016 and 2019, emphasizing the demand for transparency in the product development process. The made-to-order model allows the hiring of more regular, out-of-season, garment workers who may struggle outside of key production periods. There is also the issue of excess stock: in the made-to-order model, this is no longer a concern. The new emphasis on made-to-order products is providing both accolades and dividends to designers. This year’s International Woolmark Prize winner Richard Malone has discussed how he favors the on-demand model as a way to ensure his clothes are the best possible quality. To read more about the dangers of fast fashion, and the arguments about why made-to-order could be the way forward, check out our Techpacker article.

Technologies to assist the on-demand model

A clear solution to the COVID-19 pandemic is therefore to embrace made-to-order as the future of fashion. Using digital software like Techpacker can make this transition easier and infinitely faster. Through our app, you can establish a clear and consistent channel of communication with your manufacturers. Designer Daniella Samper of Ajaie Alaie, who recorded a podcast interview with us at Techpacker, has credited our software with allowing her to send updates to her manufacturers instantly. Daniella, who switched to made-to-order manufacturing during the pandemic, has said that Techpacker has made this process seamless through its clear communication channels. For example, Techpacker provides a clear record of your communications with your manufacturers, so no orders go missing. It also allows you to keep up to five manufacturer details saved, so your orders can be sent out in seconds.

Likewise, retail platform Shopify is also pushing the made-to-order model. Shopify is an e-commerce site which has promoted the new production model as a way to eliminate waste and gain a better cash flow. The site is completely cloud-based and allows designers to sell their wares from anywhere in the world, with no minimum order quantities. Likewise, Sharecloth is specifically designed to digitize fashion business and focuses its software for on-demand designers. The app allows customers to access orders through either their website or the software, maximizing the potential profits. The site also partners with production and delivery groups, making it a good place for brands just starting out with the made-to-order model.

In the time of COVID, where manufacturing is already facing insecurity, this is a small way to help mitigate the supply chain crisis through technology. And, as Daniella found, software can help you approach the made-to-order model to help maximise the future of your brand.

To learn more about Techpacker’s approach to On-Demand fashion, why not read our article about it here. You can also sign up for a free trial on our homepage where you will be given a free onboarding session to get started.