Contents

Once your base size pattern is created, fit is adjusted and perfected, what’s next? You’ll use what’s called pattern grading to adjust your base size pattern to create other sizes. There are different methods to grade patterns, but the end result is that you have a consistent visual across sizes. In the end, you’ll end up with measurements for each size in your range.

What is pattern grading

Pattern grading is the process of turning a sample size (sometimes referred as base size) into an additional smaller or larger sizes. Pattern grading is done using a size specification sheet. Grading does not create a new shape, it increases or decreases the size of the original shape of the garment.

History of pattern grading

The main purpose of pattern grading is to proportionally increase or decrease the size of a pattern, whilst also maintaining the same fit and shape of a garment.

Historically, because of mass production, and with the advent of commercial patterns, the science of grading was developed in the 19th century. A pattern needed to be graded to a range of sizes to properly fit on different body types. Nowadays, clothing manufacturers and pattern makers use a middle-sized pattern (typically size S or M) as a base and grade it up or down for larger and smaller sizes.

Methods of grading

There are 3 basic methods of pattern grading:

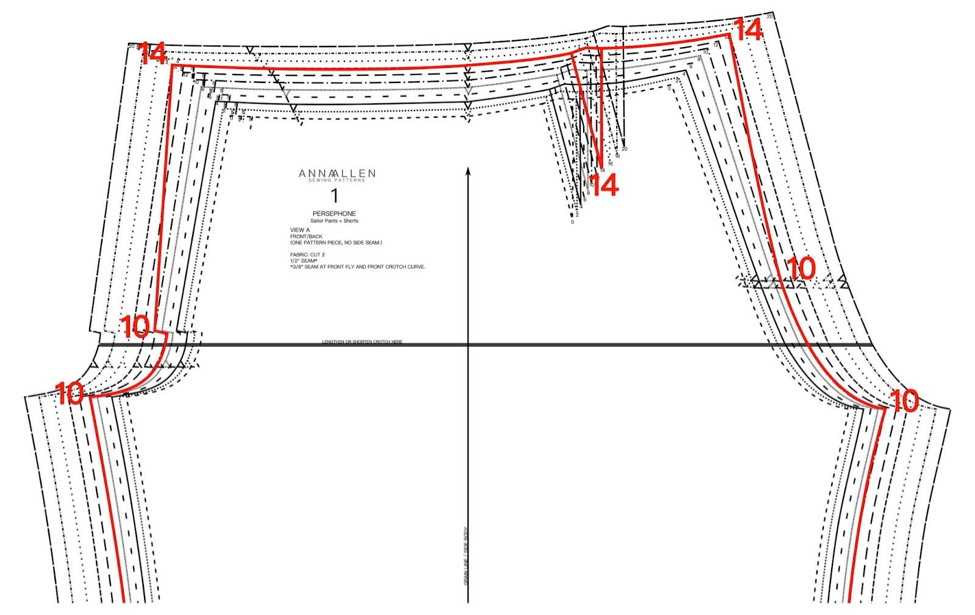

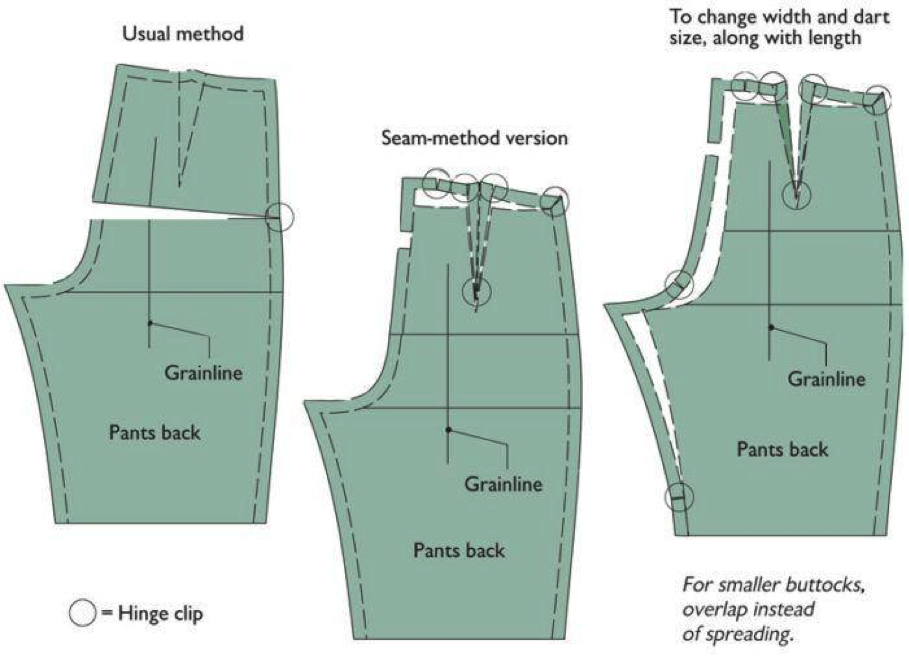

Cut and spread

This is considered the easiest method. It is performed by cutting the pattern and spreading the pieces by a certain amount, to grade up or down. The only tools needed are a pencil, ruler, scissors and measuring tape.

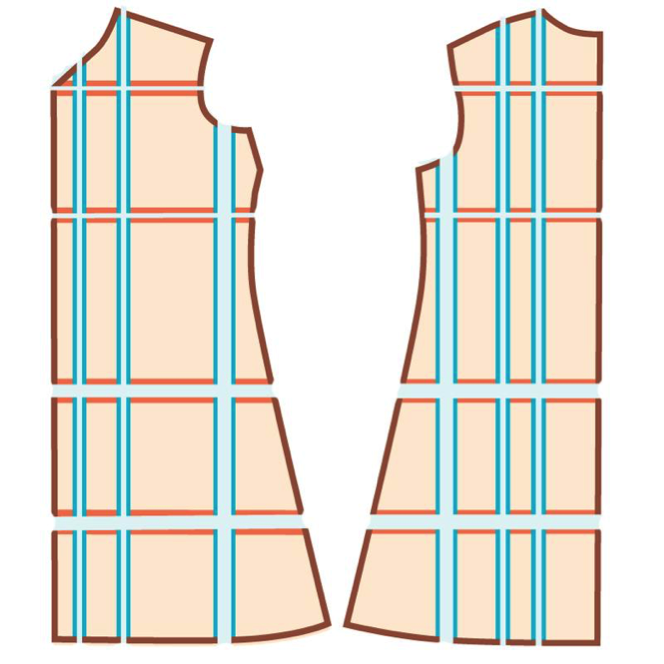

Pattern shifting

This method is done by moving the pattern around at a constant distance. The designer redraws the outline in order to produce the same results as the previous cut and spread method.

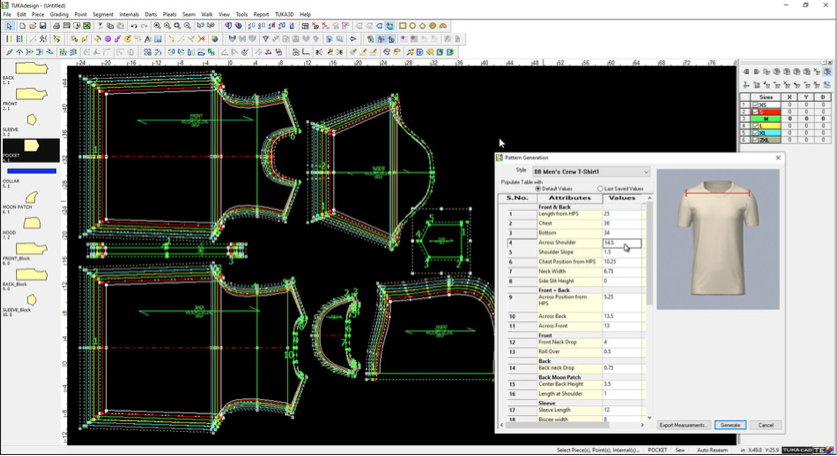

Computer grading

Has developed with the advance of new technologies. It is considered the fastest method. It basically uses the same process as the ‘cut and spread’ and ‘pattern shifting’ methods and digitizes them.

Difference between grading a pattern and altering a pattern

Grading a pattern and altering a pattern are two very different and separate processes. When you grade a pattern every measurement point is changed based on a strict formula. Garment maintains the same fit and proportion in each new size. Basically, you are creating the same style in another size.

When altering a pattern, only some parts of the pattern are changed. The same fit and proportions are not maintained, a new size is created for a specific custom size. For example, the shoulder width stays the same, but the bust circumference is adjusted to a bigger size.

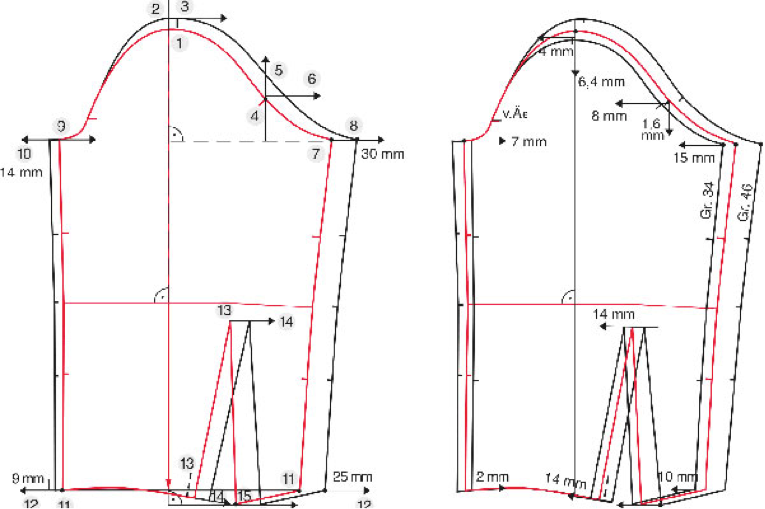

What are grade rules and grade rule libraries

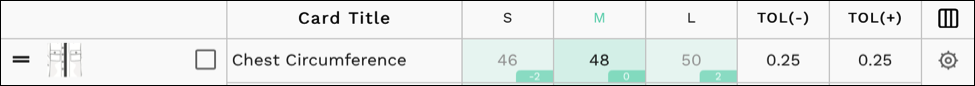

The grading rule determines how much each POM (point of measurement) is made larger or smaller in order to fit a wide range of sizes. The main purpose of it is to ensure good fit and overall balance of shape in a manufactured garment.

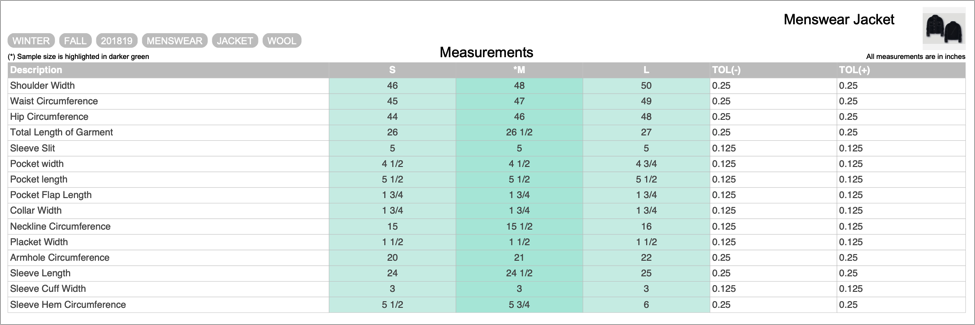

For example, the grade rule will determine how much the chest measurement will decrease or increase in size. In a standard size range this POM ‘grades’ 1-2 inches between sizes. If your sample size is M and you are making a size L, you’d make the chest 2 inches larger:

The/A grade rule library is basically a collection of grade rules. It is used to grade the whole pattern according to the desired size specifications. Grade libraries vary according to design features, fabric properties and the type of grade. For example, the grade library for a knit pair of pants will be different from the grade library of woven pants in the same style.

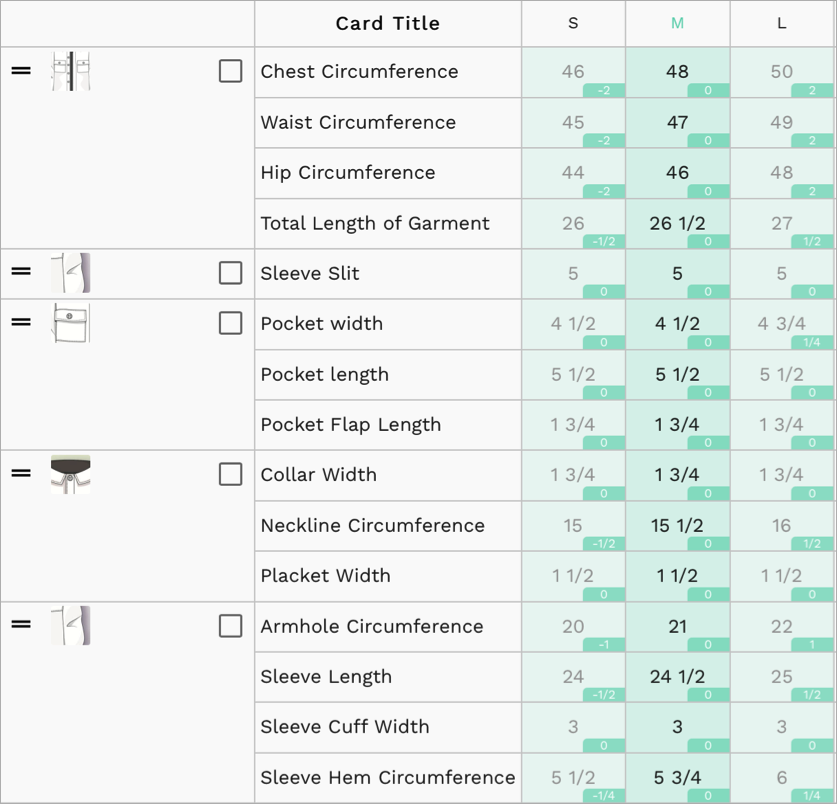

What are grade specs

Grading specifications or grading specs are the measurements that indicates how much you want each size to change, by becoming larger or shrinking. They are essentially providing the factory with the same information as your grading rules.

However, this is delivered in a different format and with more information included. Take a look at the following example:

Some designers agree that the grade specs are more complicated and therefore allow more room for mistakes when manufacturing a garment. When using a graded spec, designers will have to update it every time any of the sample’s measurements are changed, which happens a lot during the sample making process.

As technology advances, most grading is done by computer. So, nowadays graded specs aren’t always needed for mass production, unless you are working with a small factory. In big volume production, patterns are going digital and all you need to do is to enter the grade rules and let the computer work out all the needed sizes for your pattern.

How to create grade rules and grade specs

When designing clothing for the mass production a bespoke grading rule system is used. The main factors that are taken into consideration are age range, style preferences and garment usage. In addition, the desired position of the brand in the current market is also taken into account, as are the demographics of the brand’s customers.

Using the bespoke grading rule system maximizes exposure across the sizing spectrum, as well as aligning the brand with the sizes of their competitors. Customers get used to standard sizes and fit, which potentially reduces the number of returns for brands.

However, with the rising popularity of custom-made clothing, g creating a ‘unique to your business’ grading rules system is a thing to consider.

Your grade rule will mainly depend on the style they are creating. If you are designing sportswear the size pattern should contain enough allowances for the ease of movement. For a boxy garment, each size will need to include extra room for an oversize fit.

To create grade specs, you will need to figure out the sample size measurements first. Some of these measurements will come directly from your body data, while you’ll add the garment ease amount to others.

These include the following basic points of measurements:

- Full garment length

- Chest

- Waist

- Hip

- Sleeve length

- Neck width

- Front neck drop

- Across shoulder

More complex garments will have more points of measurements. For a button up shirt, POM like collar stand width/length, collar width/length, button up placket length and width will need to be included.

Then you will determine how many sizes you would like to go up or down.

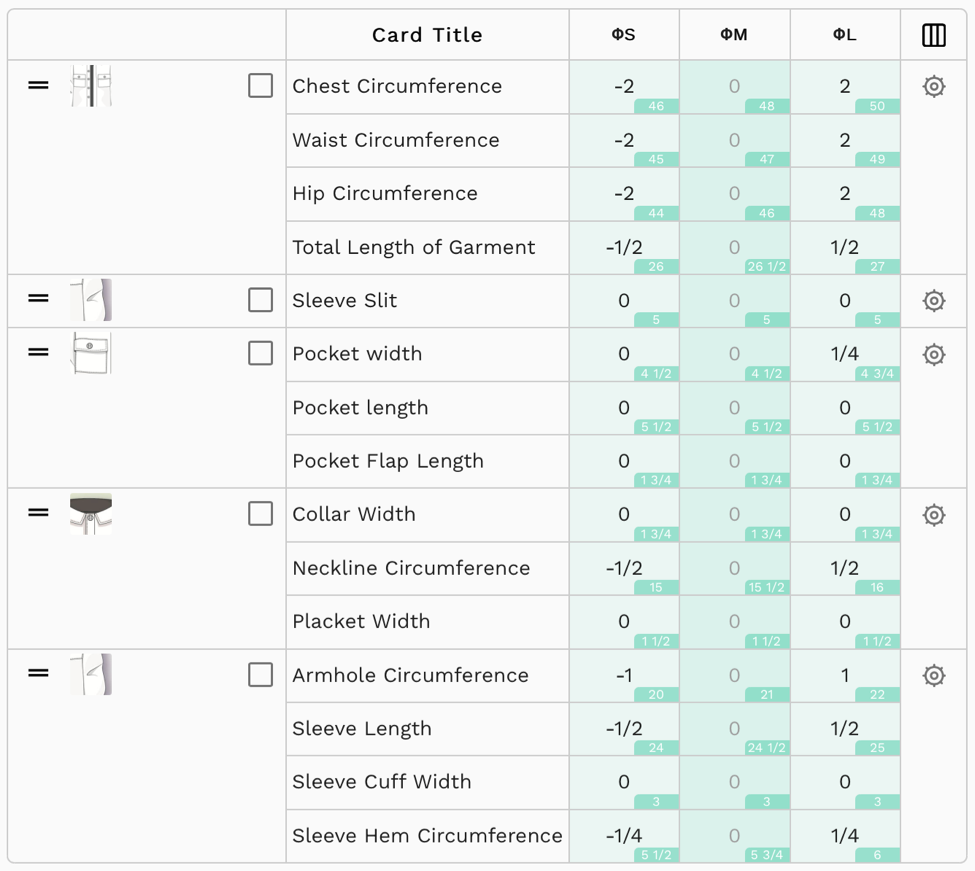

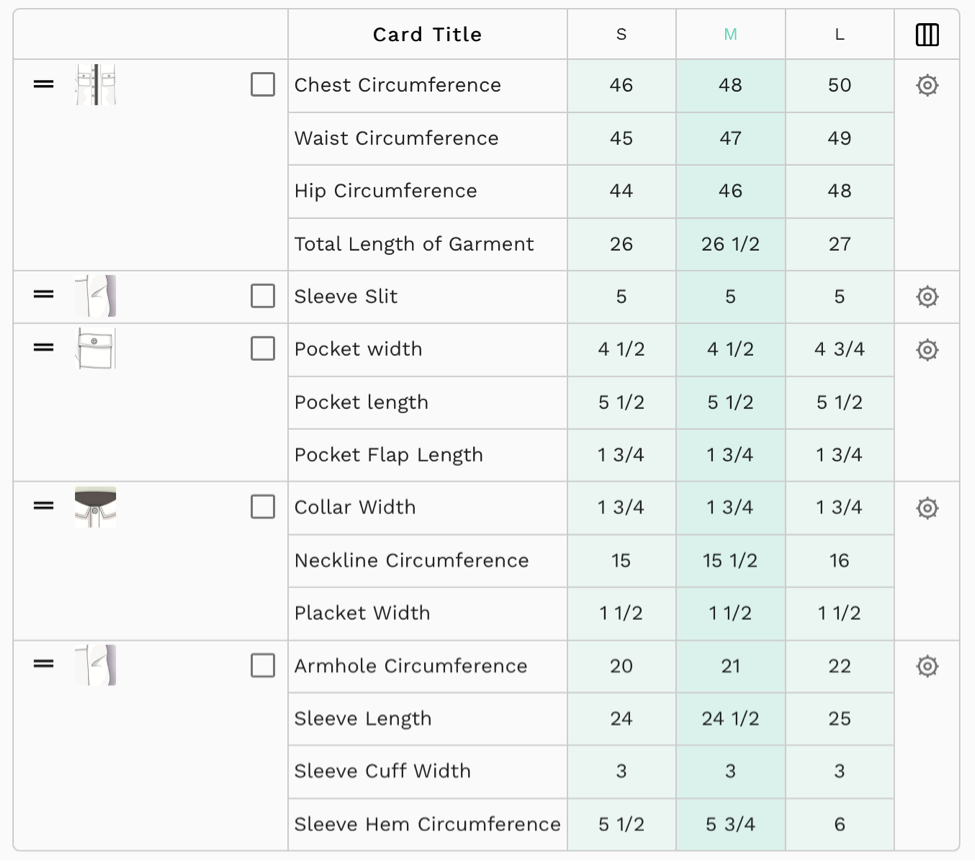

After adding your points of measurement, the grade rule is added to calculate larger and smaller sizes based on your selected sample size.

Product development software like Techpacker helps you to calculate measurements of all sizes much faster, based on your provided sample measurements or your own grading rules:

{VIDEO} How to make a grading specs sheets?

|

Interested in trying out this grading feature? OR Request a demo

Manage your product development to production workflow with factories hassle-free. Try Techpacker. |