Contents

Have you ever wondered why the Bill of Materials is so important? First of all, it’s impossible to manufacture a garment without one. Second, creating an easy-to-read, well-defined Bill of Materials is crucial for product development. Want to learn how to create an effective BOM for your Tech Pack? Read on!

Simply put, Bill of Materials is your production recipe and shopping list. It is the complete list of ingredients required to produce a finished and sellable garment. A well-defined BOM helps you manufacture your product efficiently and cost-effectively. In this article, we will talk about what the Bill of Materials is, why it is important, what to include in it in order to create an effective Tech Pack along with some examples. We will also share tips on how to get the best pricing from your suppliers, how to calculate the cost of materials, and will answer an important question - why is it important to audit a Bill of Materials?

What is bill of materials?

Bill of Materials (BOM) is a complete list of all items with corresponding costs and quantities that are required to build a product whether it’s a piece of clothing, shoes or accessories. BOM helps companies estimate material costs to plan purchases and reduce waste. It also helps you never miss a single thread, button, zipper, or tiny detail when manufacturing your products.

Bill of Material is a list of raw materials needed to be sourced to make a garment and make it ready for shipment. When your business makes a physical product, you need to source the materials to make it. Sourcing materials is an important part of the production process. The materials you choose make a huge difference to the quality of your product.

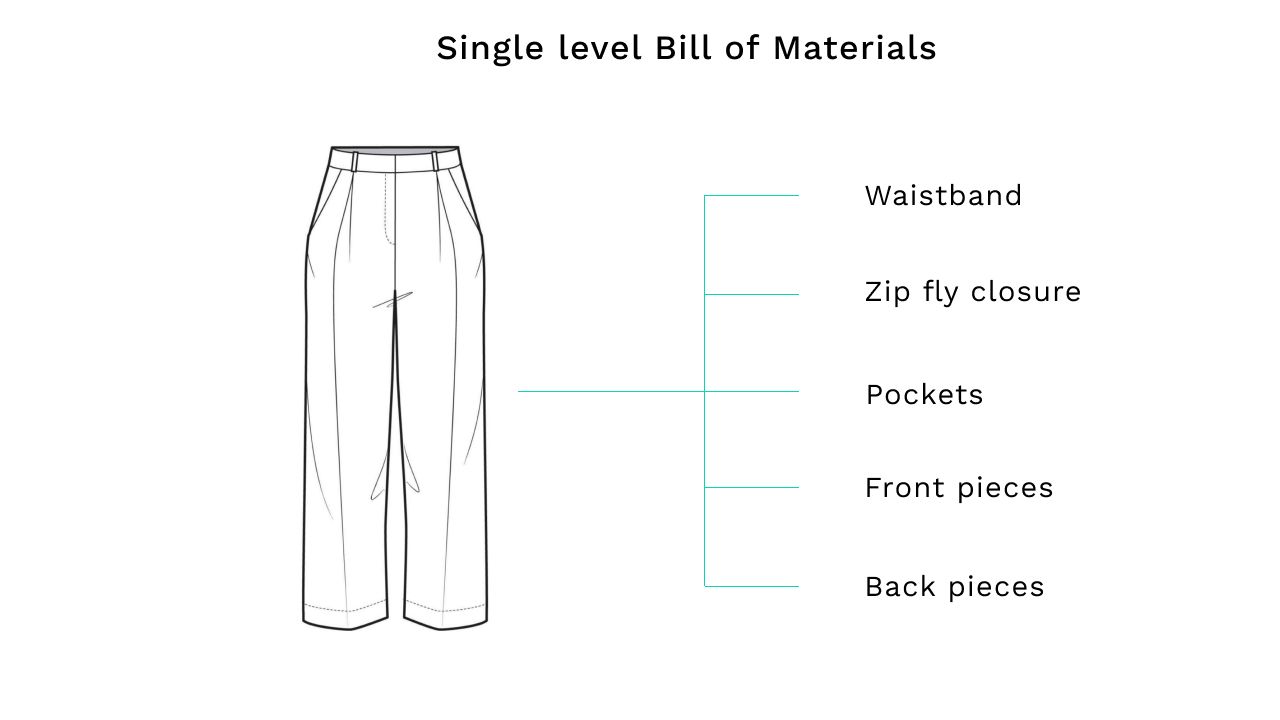

Depending on the complexity of a garment or an accessory and the number of assembly or sub-processing steps required to make it there are several levels of a Bill of Materials:

→ Single-level Bill of Materials: It is a simple list of materials needed to manufacture a product, where each assembly or subassembly is shown only once, with the corresponding quantity required of each detail to make the product. A single-level BOM is the simplest list for manufacturing a product. It can be used where there are no complex processing steps or sub-assemblies.

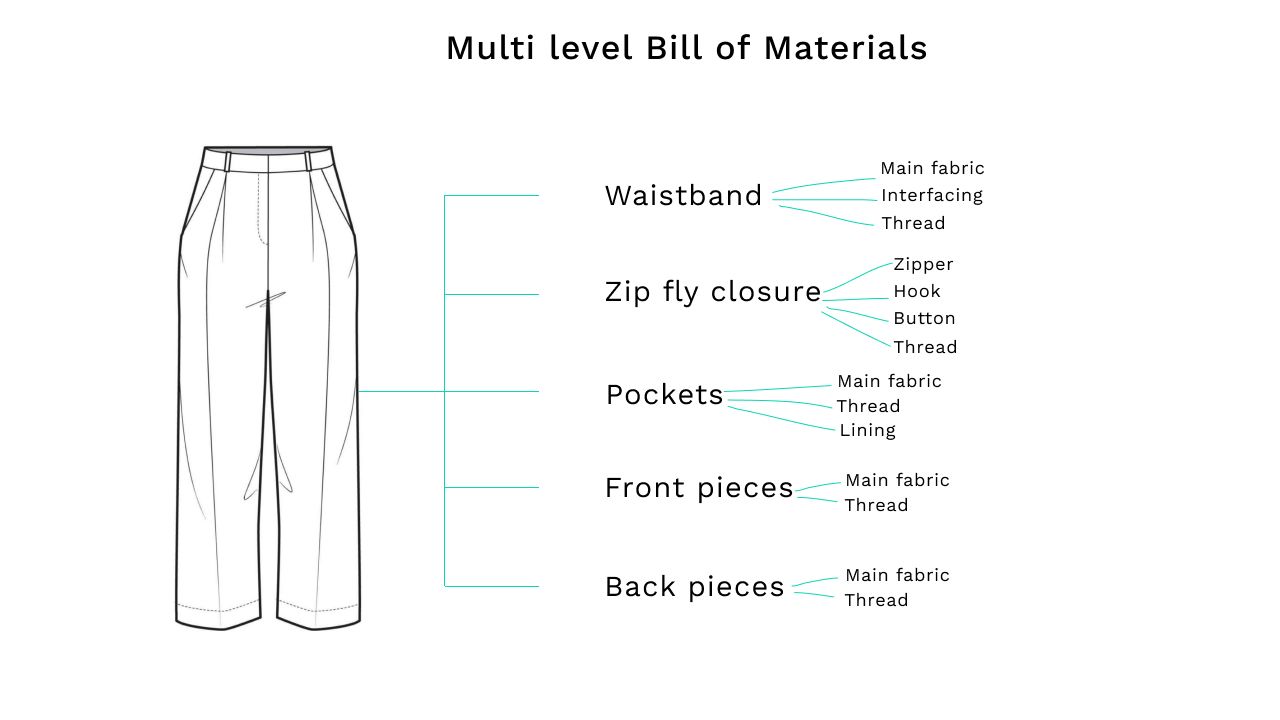

→ Multi-Level Bill of Materials: This type of BOM is more common. In a multi-level BOM, the list also contains the materials and quantities used in each step. This allows for the creation of parent/child relationships and can allow more complex and accurate costing down to the raw material stage.

To compare here is an example of a Single-level Bill of Materials on a pair of pants.

As you can see a Multilevel Bill of Materials has a more complex structure. It includes all the little details that go into a finished pair of pants, including a zipper, a hook closure, button, and interfacing.

Sign up for our FREE membership and get access to

All premium articles

E-courses and ebooks

Ad-free experience

Tech pack templates

Who Prepares Bill of Materials?

In the apparel industry, a Bill of Materials is often created by a technical designer. A technical designer is an integral part of a fashion design team, working closely with fashion designers, manufacturers, and merchandisers to create a high-quality product. A fashion designer comes up with the concepts for the designs. A technical designer executes the design, coming up with patterns, material, etc. The technical designer works closely with the manufacturer, sends the comments to the factory, and adjusts the Tech Pack accordingly. Technical designer creates a Bill of Materials based on a CAD (Computer-aided design) drawing.

It is very important to provide a detailed CAD drawing of your finished product. It is true that most designers still prefer to put the initial sketches on a piece of paper. However, many now translate those outlines into digital formats.

Till some time ago designers used to pore over a drafting table, using paper, pencil, and eraser, and draft every detail by hand. The advent of software systems like CAD (computer-aided design) has made drafting easier and less time-consuming. CAD software technology is capable of creating objects in two-dimensional (2D) and three-dimensional (3D) space. It can also include measurements, provide information about the materials, tolerances, processes, and other symbolic details. A detailed CAD drawing can speed up processes that are laborious and time-consuming. The main advantage of using computer simulations includes bringing down the production costs and speeding up the design production cycle. Clothing design software like Adobe Illustrator and Marvelous Designer is also pivotal in making garments to specification. The use of design applications enables fashion brands to recreate realistic drawings. Software like Marvelous Designer even allows you to see your garment in action - how it fits on a model and how the fabric behaves when she moves, how cool is that?!

CAD illustrations show exact pattern requirements such as seams, print placement, fabric cuts, and color. The greatest advantage of CAD drawing over hand drafting is the reduction in design time, which leads to reduced design costs. The drafting must create accurate drawings, and any error can have catastrophic results leading to poorly constructed garments. CAD software ensures total accuracy of measurement with a few simple commands, thus saving time. CAD enables storing of earlier design templates in the computer so the design process need not be started from scratch for each new project. Existing templates can be customized to fit the requirements of the new project, reducing the design time.

Among the benefits of using the CAD drawings in Tech Pack:

→ Saves time in production by providing an accurate detailed drawing;

→ It’s easy to read so it reduces errors in the manufacturing process;

→ It’s simple to learn. Fashion design software is easy to implement, and there are many courses available to improve your skills.

Why is Bill of Materials so Important?

Imagine it as your list of ingredients as if you were following a recipe. If it's not on the list, it won't end up in the dish you make. If you're missing ingredients, it is very likely the quality of your final dish won't be good, or worse yet, inedible!

A Bill of Materials is behind every production order. It would be very difficult to schedule and start production if there was no guide telling the factory what parts are required and how they fit together. And a BOM is a standardized method of assembling a final product for shipping and sale.

3 Reasons why BOM is important:

1) To determine costing and pricing. As each component is listed and detailed with its respective quantities (with up-to-date prices), it should reflect the real cost to make a garment in the current market. This can help you determine profit margins and come up with an adequate pricing strategy for your product. Here you can start to calculate the raw-material cost for garments.

2) To ensure your factory doesn’t miss any components. Listing materials and defining them in the same sequence used to manufacture assures the garment will be constructed as needed. Imagine an engine in a car factory. If all of the components required and the correct order to build it are not specified, it won't ever run! With garments sometimes you can be less strict about the sequence, but experts assure it's better to establish an order to prevent production mistakes. If you end up making a piece of clothing that misses one of the essential components and therefore fits poorly it won’t sell!

3) To standardize manufacturing. As you know, a garment can be run through several processes from its inception until receiving the final order. All of the steps it undergo depend on the garment's purpose, design, target market, etc. The BOM helps present this process flow and aids in understanding how the raw materials are converted into the final product. Once the BOM is defined, it can be used as part of the Standard Manufacturing Process to ensure quality and consistency in every batch.

Manufacturing operations are not the only ones to benefit from a detailed BOM. Management, sales & marketing, customer support, and purchasing all benefit from the additional data provided by BOMs.

For service and repairs, customer support staff have a clear representation of what exactly goes into a dress or a pair of pants you are making as well as their quantity. So, for example, if the product returns jump due to poor design or defective zippers, they can pinpoint the affected parts and inform the design team to eliminate the problem.

For the sales and marketing teams, having a BOM for each product in the catalog can help them to craft a value proposition. One selling point could be the number of little details that go into making a finished garment.

For inventory management, it’s far easier with a BOM to plan ahead and purchase the number of parts. A production order deducts the correct quantity of stock for each raw material used for an accurate report.

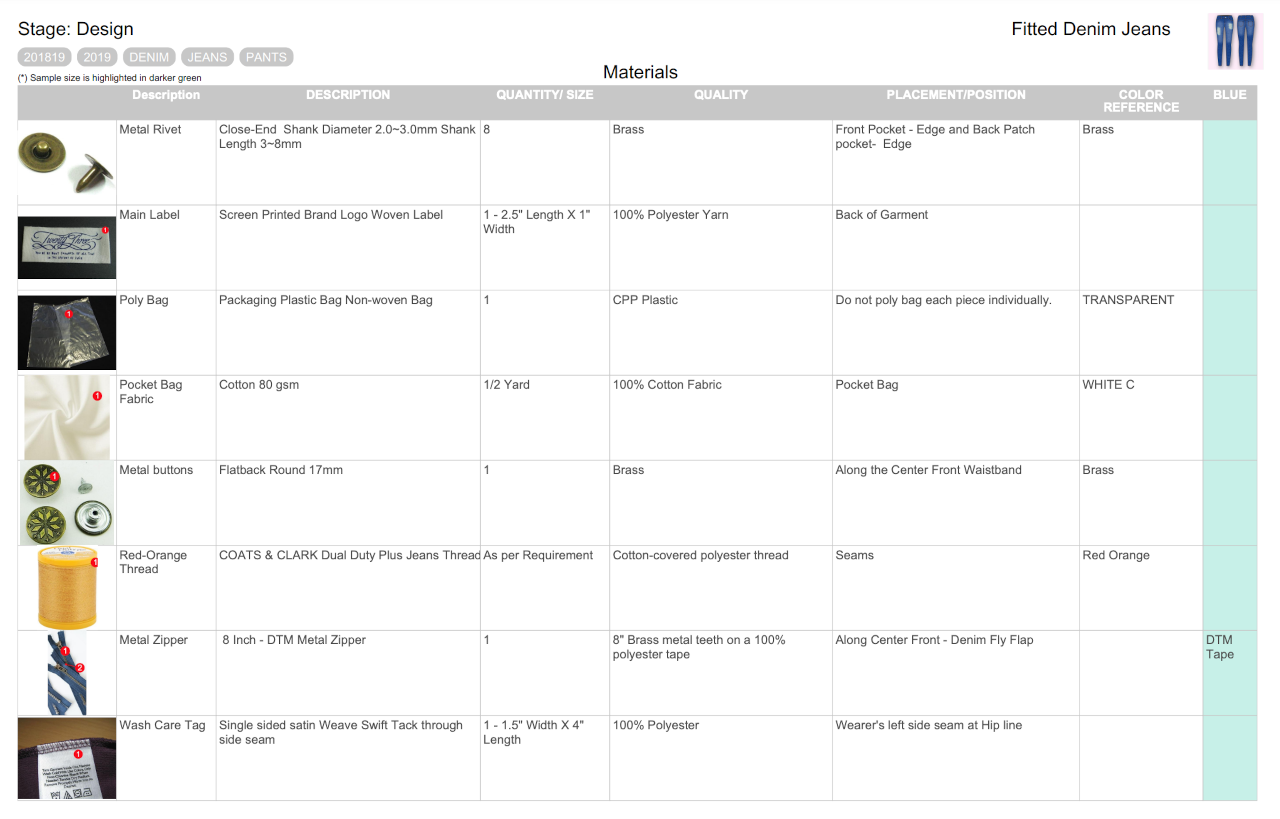

What to Include in the Bill of Materials?

Every little detail that goes into making a product has to be accurately specified in BOM in order to avoid mistakes in sample making which can add cost and time to the process. Let’s say you are making a pair of tailored trousers with hook and bar closure - make sure to mention every detail like a zipper, hook, bar, “jigger button” in your BOM. Add supporting documentation, such as computer-aided design (CAD) drawings, part datasheets, and assembly instructions. The more specific you are the more accurate sample you get. If your BOM is easy to read and comprehensive, your factory will get a better sense of the finished product.

Bill of Materials is also specific per colorway. If you have three colorways, you will need a BOM for each color.

Other essential elements of an effective Bill of Materials:

1) All parts should have assigned numbers and unique names so you can easily keep track of them;

2) BOM Level: The hierarchy of the part or assembly;

3) Exact type of material has to be specified including trims, embellishments, and notions;

4) Color. Add a Pantone number to make sure the right color is used;

5) Labels and packaging: hang tags, care labels, size labels, hangtag thread, pins, tissue, poly-bags, and desiccant bags, etc.

6) Quantity of each part used in each assembly;

7) Unit cost: the cost per unit of the part;

8) Unit of measure. Standard measures include pieces, centimeters, inches, feet, and yards;

9) Description: additional notes about each part;

10) Who BOM is approved by and approval date;

11) Total number and total cost;

12) Supplier. Record the name and contacts of the supplier that provides the parts to easily get access when you need to order more.

13) A bill of materials may include not only the unit quantity required to construct a finished product but also an estimate of scrap that will occur during the production process. Scrap is the excess unusable material that is left over after a product has been manufactured. This residual amount has minimal value and is usually sold off for its material content. A business can reduce the amount of scrap that it generates by exercising great care in setting up production equipment, buying raw materials of adequate quality, and training employees in the proper use of production equipment;

14) It can also include such things as the required processing (sponging, dyeing, etc.) and test results like shrinkage of the fabric. Some of the fabrics tend to shrink during the manufacturing process, therefore it’s important to do some research on the fabrics that will be used and to do some tests like pre-washing the fabric before sewing the garment.

This document must be extremely accurate. Otherwise, an organization may order incorrectly from suppliers and pull the wrong items from stock for a production run, which can result in major delays in the production process. Manufacturing operations are not the only ones to benefit from a detailed BOM. Management, sales & marketing, customer support, and purchasing all benefit from the additional data provided by BOMs.

Tracking costs through your Bill of Materials

As we mentioned before a well-defined Bill of Materials helps you manufacture your product efficiently and cost-effectively. One of the important functions that a BOM serves is to track cost. It’s easy enough to track cost when you’re just buying parts because you’re only accounting for the initial price and freight, but creating something out of a bunch of different items is another challenge altogether.

It is fairly easy for the actual cost of your component items to get lost in the mix, and this can screw the actual cost of your end product. Inaccurate costing could cause you to undervalue the finished goods you create.

When you’re putting a BOM together, make sure to track the specific costs of every detail listed. It might also be a good idea to add a date to the BOM since the costs of your products can change over time. How you price your goods will depend on whether you buy your products in bulk, or if you buy them from different vendors at differing prices.

For the profit margin, you need to add further production costs to the cost of the parts to arrive at a final cost figure. Then you can decide on an appropriate margin after accounting for sales, distribution, and marketing costs of the garment.

Learn more on how to track your costs and create an effective Costing Table here.

How to Get the Best Pricing From Suppliers?

Like most brands and designers, you’ve often wondered whether the price quoted by your supplier is "reasonable” and if you could get a lower price from someone else. You've also probably considered other important factors against price, such as quality and existing supplier relationships. With all of this in mind, (and your BOM ready, of course) check out these tips on how to negotiate the best price from your factories from our friends at In-Touch Manufacturing.

Examples of BOM table

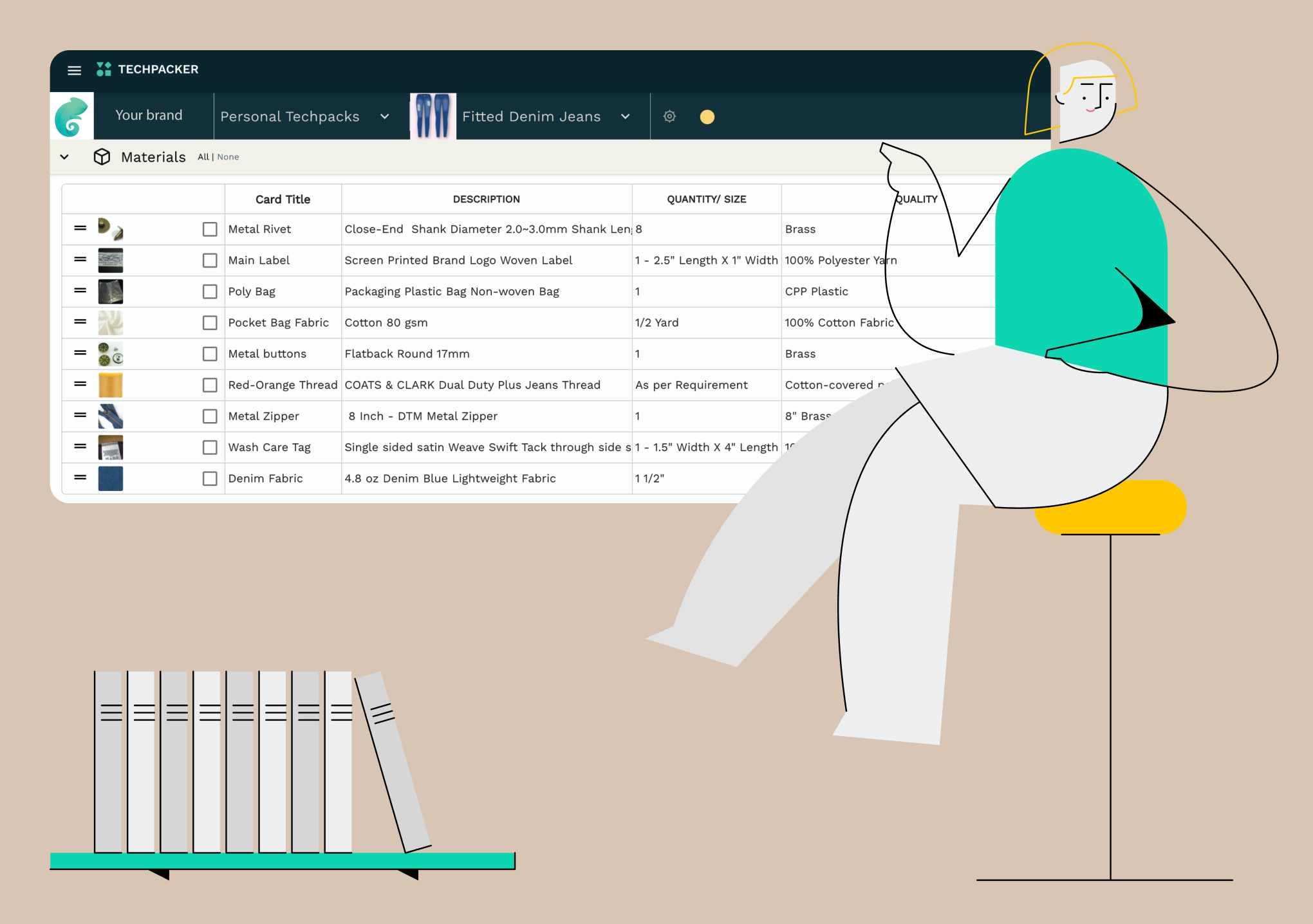

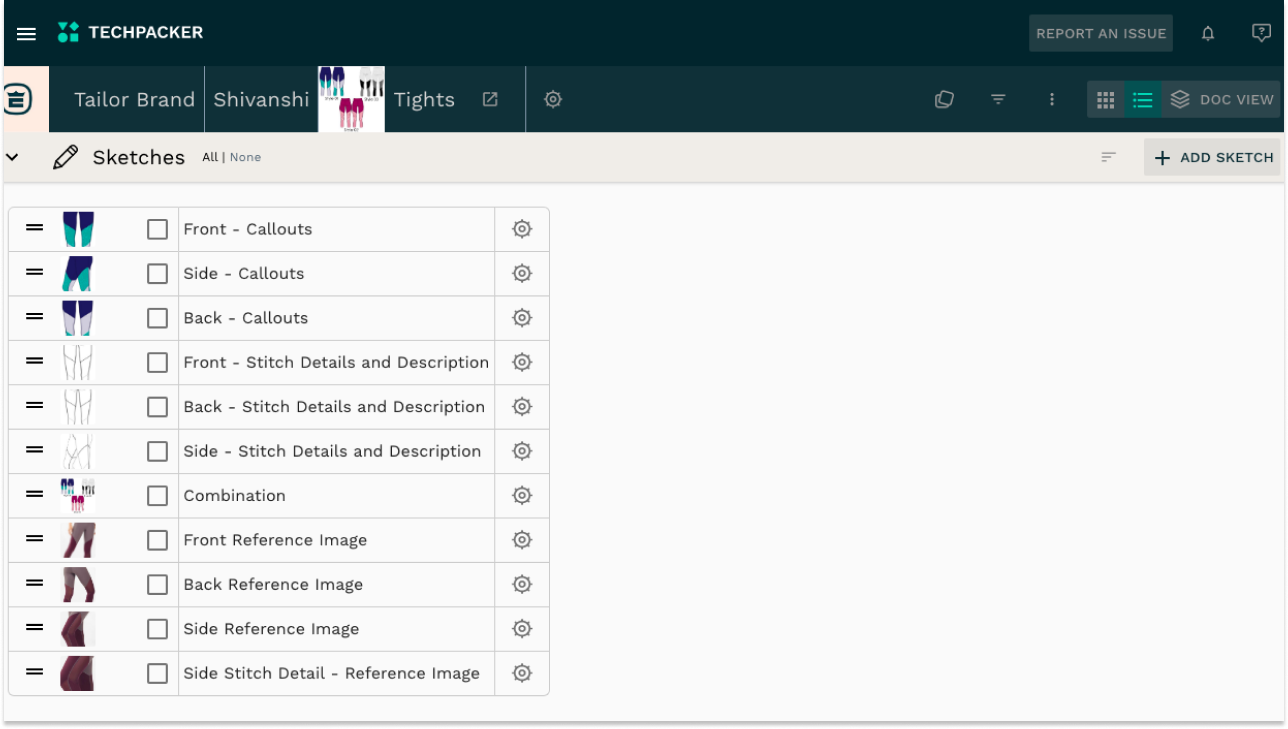

To make a well-defined and easy-to-read Bill of Materials you have to make sure to add every single detail needed to produce your final garment. Techpacker helps you make it fast and easy. It allows you to add a Materials sheet along with the Costing Sheet and Measurements.

Let’s discuss it with an example of leggings Tech Pack made in Techpacker.

Bill of Materials should include a complete CAD drawing or 2D flat sketch of a garment you are manufacturing, including the colorways. Each colorway should have a separate CAD drawing for reference.

Along with a complete CAD drawing of your finished garment Techpacker allows you to add little detailed sketches of each part of the garment. See the table below.

Using detailed sketches helps communicate with the factory and reduce a number of potential mistakes. Simply put, you need to be as clear as possible in your BOM, leaving no room for guessing for your manufacturer. They need to know every single detail of a finished product you want.

After adding sketches you fill the Materials sheet. You need to specify the main fabric, secondary fabric, tertiary fabric if needed along with the other details like elastic band, sewing thread and other notions, labels and hang tags. Techpacker allows you to add little preview cards with the photo of a material which will be very helpful in the production process.

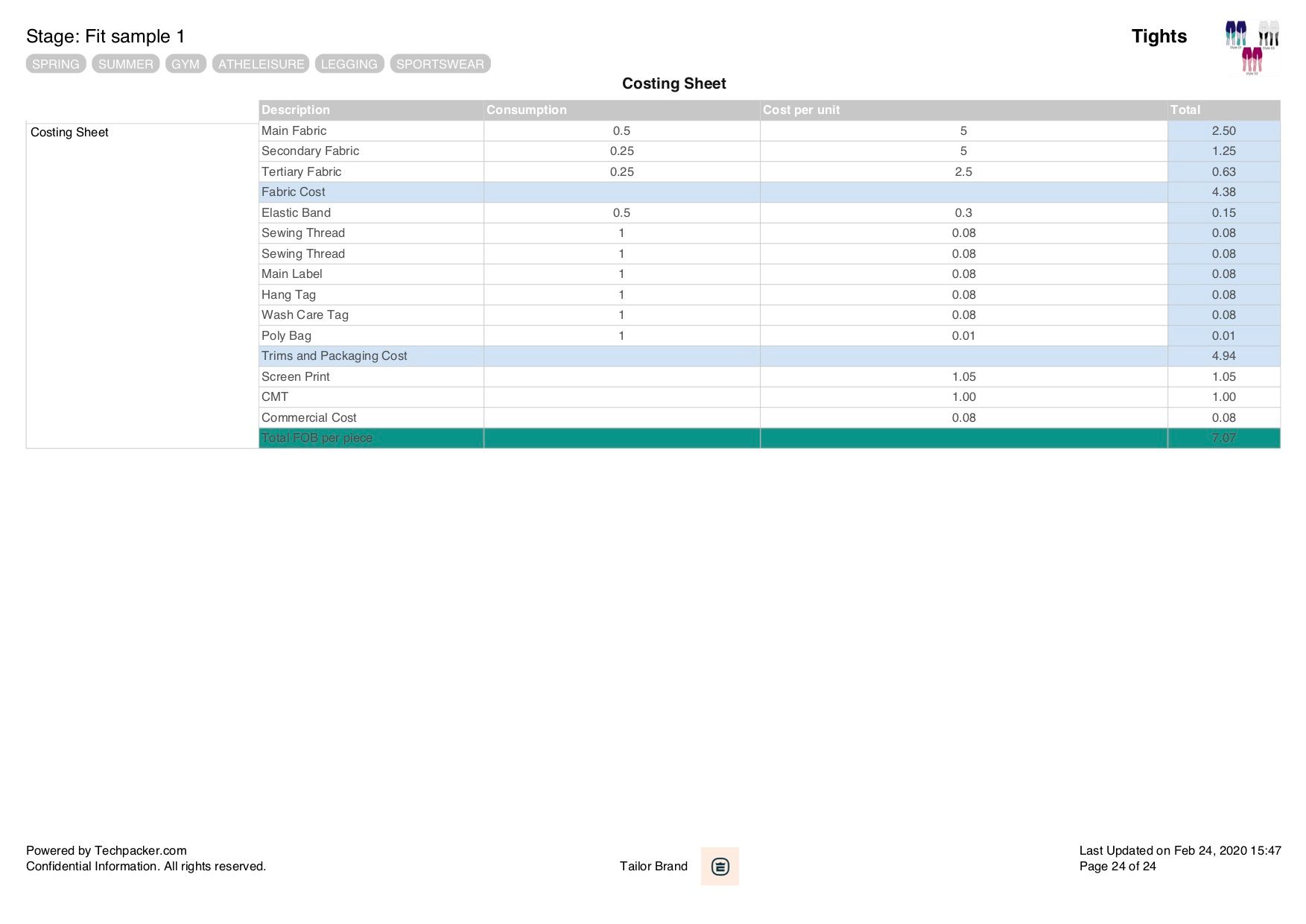

After completing the Materials sheet you want to add Costing Sheet to the materials that will be used. With the help of the Costing Sheet you will be able to calculate the final price to manufacture a finished product.

As you can see from our Costing Sheet made with Techpacker the total FOB per piece cost will be $7.07. Being accurate when filling the Materials and Costing Sheets allows you to plan your budget accordingly and know the potential cost of a finished garment.

How to Audit a Bill of Materials?

First of all, why is it important to audit a Bill of Materials? The core document used by the logistics department that drives the accuracy of the inventory is Bill of Materials. Material cost is one of the largest expenses of the company. If the inventory amount is not correct the calculated cost in the Bill of Materials can be off by a significant amount. If the listing of components is incorrect the product cost will be incorrect too. Thus, the accuracy of the Bills of Materials has a major impact on the accuracy of the cost. The solution is to audit the Bill of Materials. The review can be conducted by the engineering staff, the production scheduler, the warehouse staff, and the production staff.

- Steps to audit the Bill of Materials;

- Ensure the correct part quantities are listed;

- Verify that parts should be included in the product at all;

- Check if the subassemblies are specified correctly.

If any of these items are incorrect, a Bill of Materials should be listed as incorrect in total. The audit of BOM helps you minimize the impact of mistakes on the accuracy, cost of the inventory, and cost of goods sold.

Wait! We've Got Some Extras

Listen Up! This Podcast is all about how product development teams can use a Bill of Materials (BOM) to communicate the most up-to-date and accurate product information to stakeholders throughout the product development. Wow!

Look out! For this smart read about the future of BOM management in the age of digital manufacturing. Unlike a database-centric approach (PDM/PLM), it's now a network-centric approach that will make BOMs shareable with teams distributed worldwide in real-time. Neat huh?

Let's Summarize

BOMs are an integral part of a Tech pack and it must be done correctly to help you stay organized, keep track of production costs and also help your factory stay organized (again they will love you for it ;)

Creating and managing BOMs on Techpacker is an easy and enjoyable collaborative process. This is because Techpacker allows you to add all of your materials as individual cards and "stack them up" in a table that is easy to visualize and can be edited by you and any member of your team.

Plus all of your Material and Costing Sheets can be saved in an organization-wide library, making it efficient for your team to reuse instead of typing them all over again. Simply drop the Material and Costing Sheets on your design board and print or send a PDF version of your Tech Pack just in one click.

Yes! It’s that easy!

|

Ready to Create your own professional BOM with Techpacker? OR Log-in to your account now

Manage your entire fashion product development with manufacturers from one place, seamlessly. |

Liked what you just read? Don't miss any articles/case studies/free ebooks by Signing up for Techpacker newsletters - a compendium of top industry knowledge about the most important topics in garment product development.