Contents

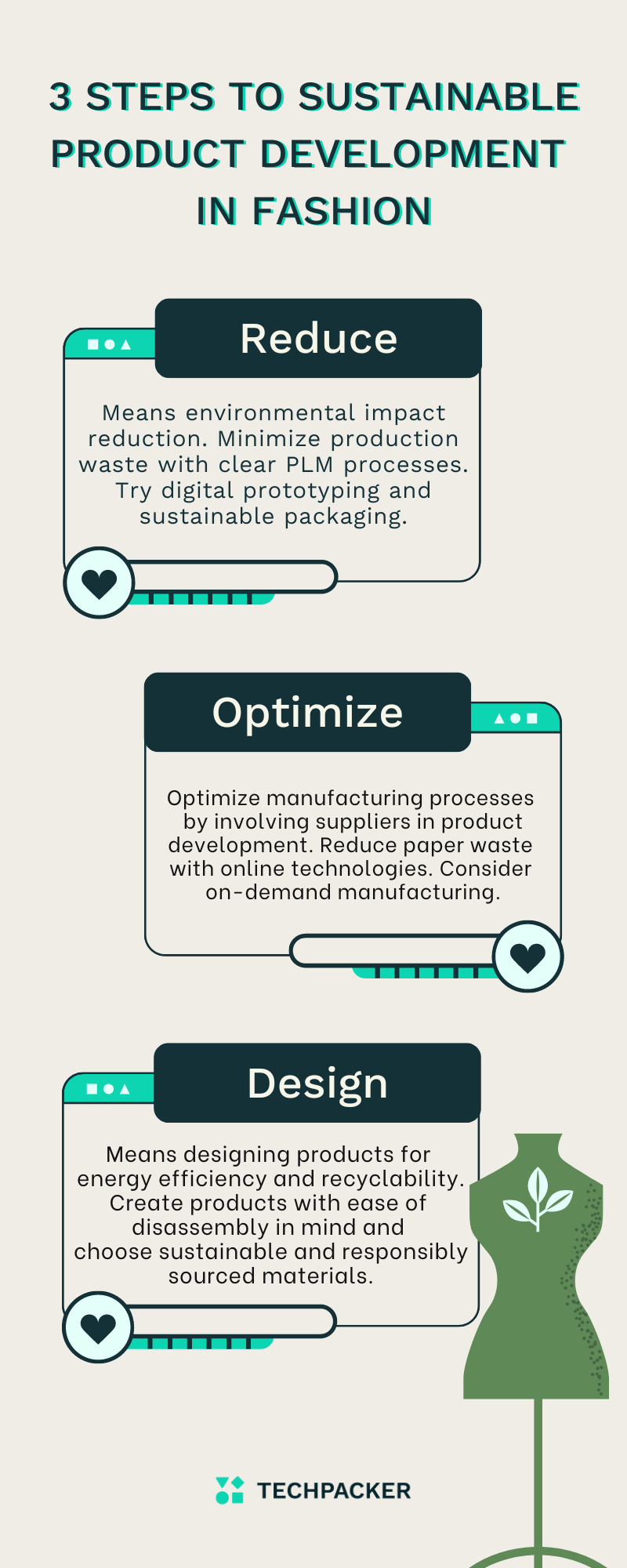

Sustainable product development in fashion refers to the process of designing and creating fashion products in a way that minimizes negative environmental and social impacts while maximizing positive contributions to sustainability. It encompasses the entire lifecycle of a product, from conception and design to sourcing, manufacturing, distribution, and end-of-life considerations.

In this blog post, we go through several sustainable product development techniques that a clothing line may use to lessen its influence on the environment.

Environment impact reduction

Environmental impact reduction in fashion refers to the efforts and strategies implemented to minimize the negative consequences of the fashion industry on the environment. It involves addressing various aspects of the fashion supply chain, from raw material extraction to manufacturing, distribution, product use, and disposal. The goal is to mitigate environmental degradation, conserve resources, reduce pollution, and promote sustainable practices.

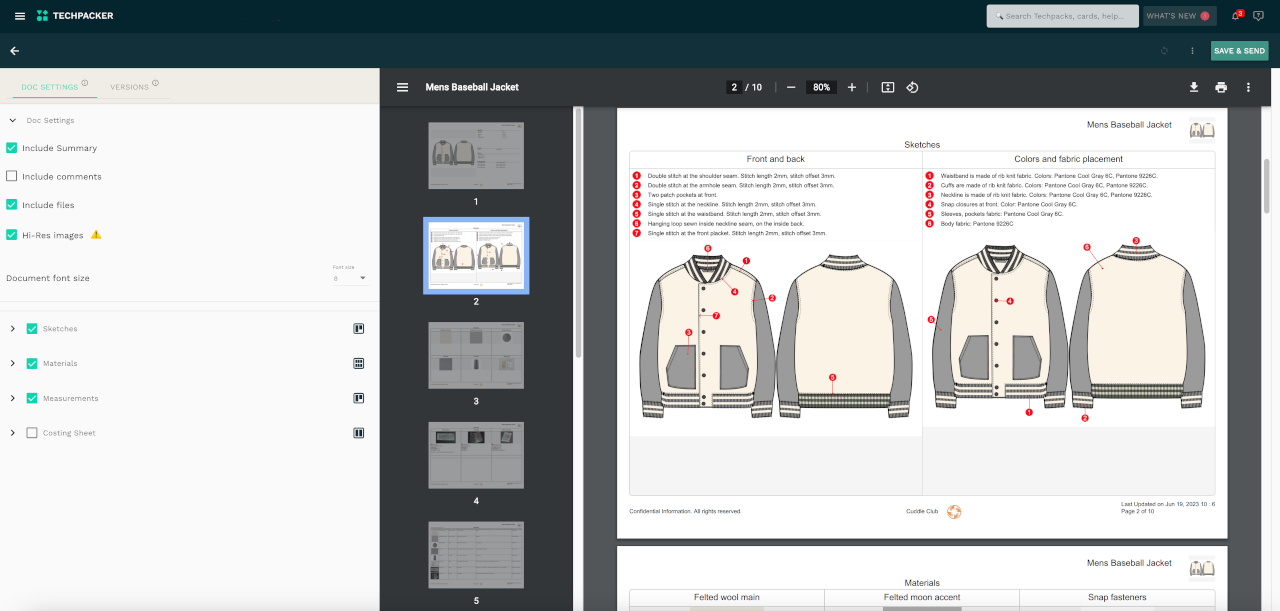

Minimizing sample-making and production waste with clear PLM processes

Clear and effective product development methods can help to reduce sample-making and production waste. With the help of modern PLM tools, you can connect all team members and suppliers under one roof, collaborate in real-time and create a more sustainable product development process together.

With the help of PLM systems your design team can:

- Foster effective collaboration and communication among the product development team, including designers, engineers, and manufacturers. Clearly communicate design concepts, specifications, and any updates to minimize errors and reduce the need for multiple iterations.

- Involve suppliers early in the product development process to leverage their expertise. Collaborate closely with them to ensure that materials, components, and manufacturing processes are optimized for efficiency and waste reduction.

- Standardize sizing and fittings as much as possible to reduce the need for multiple iterations and samples. This approach streamlines the production process and minimizes waste associated with customizations or alterations.

- Establish a structured sample evaluation process to ensure clear and constructive feedback. Provide detailed feedback to manufacturers regarding any required modifications or adjustments, helping to minimize errors and rework.

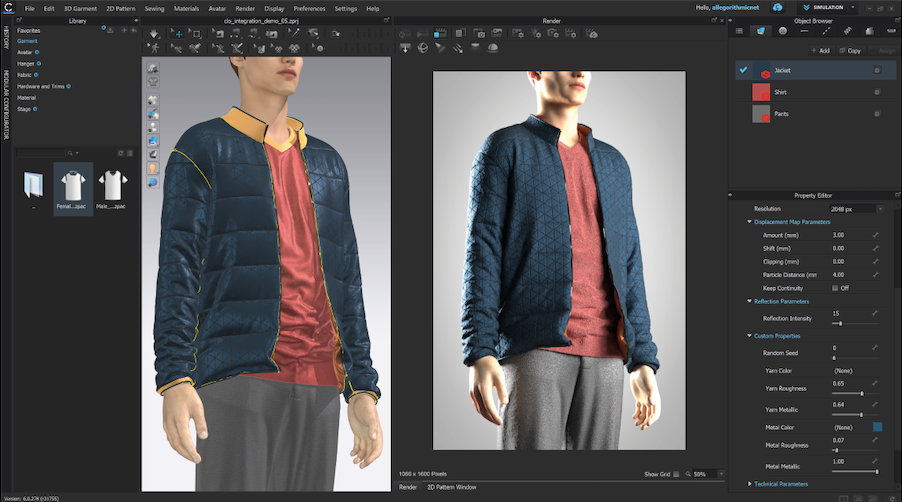

3D prototyping

Before going to tangible samples, use digital tools such as 3D software to develop virtual prototypes and iterate on concepts. This method provides for faster iterations, less material waste, and more efficient design refinement.

Implement 3D printing and rapid prototyping technologies to create physical prototypes quickly. These technologies enable the production of functional prototypes with reduced material waste, time, and cost. They also facilitate iterative design improvements.

Sustainable packaging

In fashion, sustainable packaging refers to the use of eco-friendly supplies and procedures for the packaging of clothing, accessories, and other fashion items. Brands are becoming more aware of the significance of reducing the environmental effect of their packaging across the full product life cycle as the fashion industry has become more and more concerned with sustainability.

Below are some ways that fashion brands can reduce the negative environmental impact with the help of packaging:

- The use of recycled, recyclable, or biodegradable materials is common in sustainable packaging. Options include recycled paper or cardboard, organic textiles, biodegradable polymers, and even novel materials such as mushroom-based packaging.

- Many fashion brands are attempting to decrease the number of packaging materials needed, with the goal of creating simple designs that sufficiently protect the product. Less waste is produced by removing superfluous packaging, inserts, or needless layers.

- Some fashion manufacturers are creating packaging that can be reused, such as boxes that can be used for storage or shopping bags that can be reused.

- Using environmentally friendly printing procedures, such as water-based or soy-based inks, eliminates the usage of toxic chemicals while also minimizing environmental effects.

Optimizing manufacturing processes

Optimizing fashion manufacturing processes is essential for improving efficiency, reducing waste, and minimizing the environmental impact of the industry. Here are some strategies to optimize fashion manufacturing processes:

Clear collaboration with manufacturers

Incorporate lean manufacturing principles into your production processes. This involves identifying and eliminating waste at every stage, optimizing workflows, and continuously improving efficiency. Implement techniques such as value stream mapping, Kanban systems, and Just-in-Time (JIT) manufacturing.

Involve suppliers early in the product development process to leverage their expertise. Collaborate closely with them to ensure that materials, components, and manufacturing processes are optimized for efficiency and waste reduction.

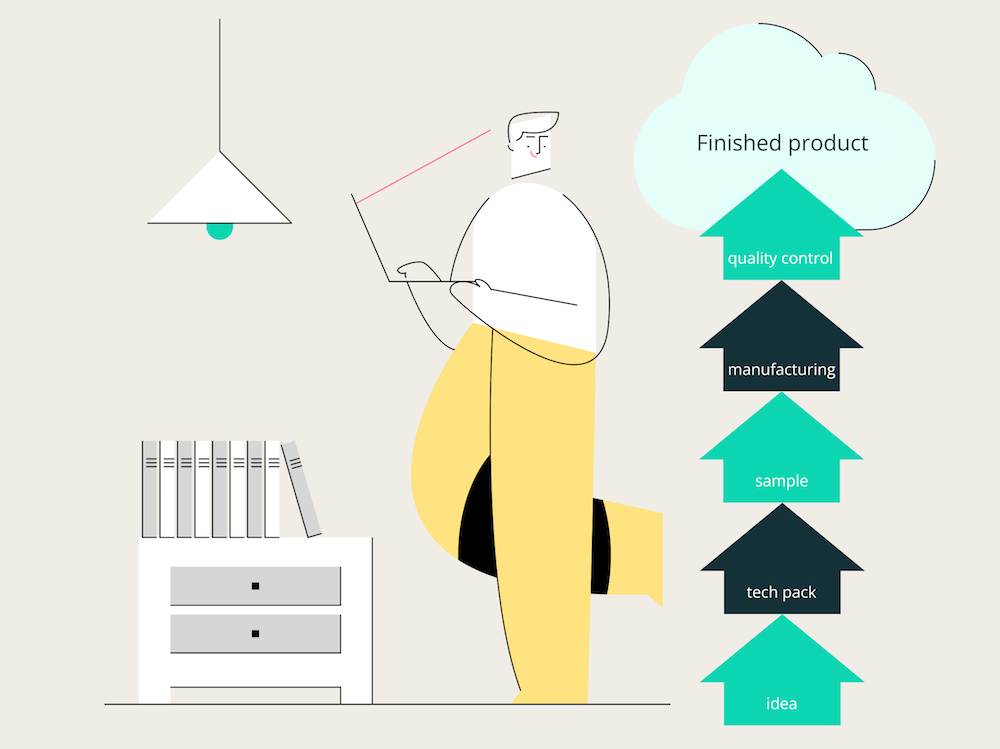

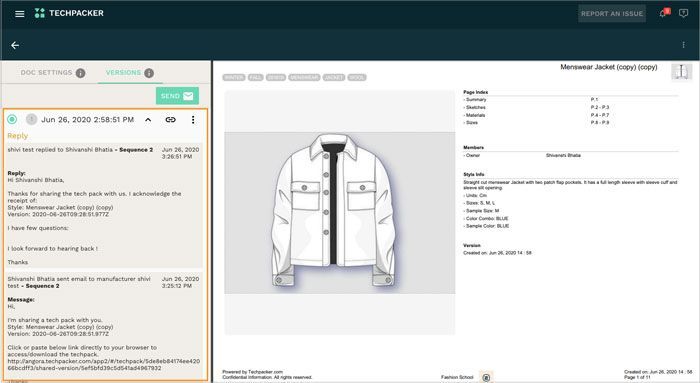

Use PLM systems to stay in touch with your suppliers and communicate in real-time. On Techpacker you can keep your conversation with the manufacturer on hand and refer to it as needed. This illuminates miscommunication, and unnecessary rounds of sample-making and therefore reduces waste.

Reducing paper waste by utilizing online technologies

With the help of PLM systems like Techpacker, you can store digital versions of your tech packs on hand and share them with your factory. This significantly eliminates paper waste when it comes to printing out tech pack sheets.

Even if the factory is not part of your Techpacker account, they can see your tech pack in a PDF format without the need to print it out. Even after multiple rounds of sample reviews, the manufacturer will clearly see all updates and edits. This significantly reduces miscommunication issues.

On-demand manufacturing

In contrast to traditional mass production, when things are built in large quantities ahead of time, on-demand manufacturing, sometimes referred to as made-to-order or bespoke manufacturing, is a production strategy in which products are only manufactured when an order is received.

There are several ways that on-demand manufacturing can support sustainable product development:

- Reduction in overproduction: Overproduction is a major problem in the fashion business, resulting in excess inventory and waste. On-demand manufacturing reduces the need to produce large numbers of clothing in advance, lowering the danger of overproduction and eliminating unsold inventory that might otherwise wind up in landfills.

- Efficient use of resources: On-demand manufacturing allows for more exact production planning, which leads to more efficient resource usage. Based on the precise amount of orders, manufacturers may optimize their material procurement, production processes, and energy usage, reducing waste and environmental effects.

- Customization and personalization: Fashion goods may be customized and personalized thanks to on-demand production. Customers may select certain designs, colors, and sizes, as well as customize their outfits. This method decreases the chance of customers purchasing many goods in order to get the right fit or style, hence lowering total consumption and waste.

- Reduced transportation emissions: With on-demand manufacturing, products are produced closer to the point of sale or delivery, reducing the need for long-distance transportation. This can result in lower carbon emissions associated with shipping, as well as decreased reliance on air freight, which is more carbon-intensive than other modes of transportation.

- Extended product life cycle: By producing garments on demand, brands can avoid the need for excessive markdowns or sales to clear out excess inventory. This helps maintain the value and desirability of the product, extending its life cycle and reducing the pressure to constantly introduce new collections.

Designing products for energy efficiency and recyclability

Designing products for energy efficiency and recyclability is a crucial aspect of sustainable product development. It involves materials selection, design optimization, and avoiding hazardous substances.

Sustainable product design

Sustainable product design involves creating products with ease of disassembly in mind, allowing for efficient separation of components at the end of the product's life. Use fasteners, connectors, or adhesives that can be easily removed, and avoid irreversible bonding methods.

Other practices include: selecting materials that are recyclable and have established recycling processes. Avoid using complex or mixed materials that are difficult to separate and recycle. Design with mono-materials or easily separable components to facilitate recycling.

Sustainable fabrics

Choosing sustainable and responsibly sourced materials is crucial to reducing the environmental impact of fashion. This includes using organic, recycled, or regenerated fibers, such as organic cotton, recycled polyester, or Tencel®. Additionally, avoiding materials associated with deforestation, excessive water usage, or hazardous chemical treatments helps protect ecosystems and conserve natural resources.

Some of the top sustainable fabrics of 2023 are:

- Recycled plastic bottles.

- Cork leather

- Pinatex.

- Microfibrillated cellulose from Spinnova.

- Econyl.

- Qmonos.

- Sateri’s Lyocell.

- Recyclable cotton.

- Linen.

- Tencel.