Contents

Even though, in essence, apparel production is not a very complicated process, there are stages we need to see through carefully before garments can be sent out for production successfully. Each and every one of these steps comes with a fair share of sample making, testing, and adjusting.

There are several ways to go about garment sampling and it’s important to know and understand the different kinds that exist to see which ones work best for your production needs.

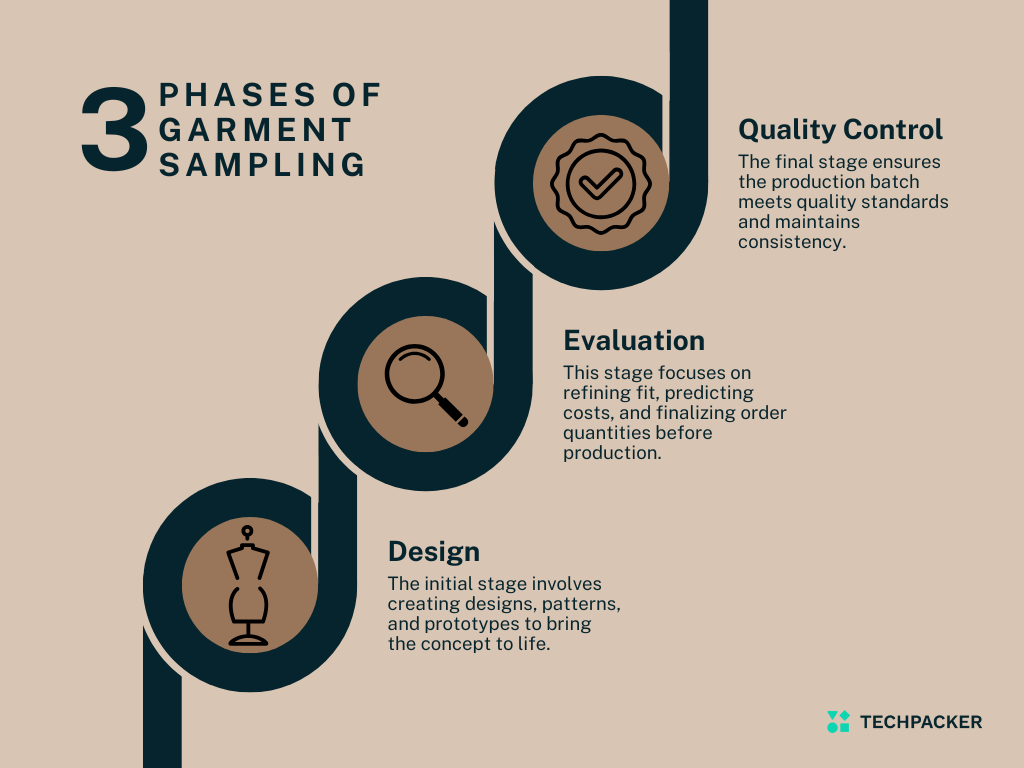

Three stages of garment sampling

When creating samples with your factories, there are usually three stages. The first set of samples correspond to the design phase, which includes everything from the initial design to pattern making. The second sample set is part of the evaluation phase which is for finalizing garment fit, predict costings, order quantities, etc.

Finally, after the collection is approved and sent to production, you will need to check samples again to ensure quality and consistency of the entire batch. These samples correspond to the quality control phase. If not all, most of these samples are essential to guarantee a top product that will not only satisfy your customers but will help make its way in today’s highly competitive market. Here we’ve rounded everything you need to know to achieve sampling success!

Get a full insight on clothing manufacturing process in this guide

Types of garment samples

Mock-up

The muslin sample is the first interpretation of a designer’s idea. Sometimes, the idea might not translate as well on paper as it does on fabric and this is where mock-up plays a crucial role. It doesn’t require any trims and its sole purpose is to test whether the garment is viable or not. Not all designs require a mock-up, so not every designer or factory works with these type of samples.

Proto or development sample

The proto sample kickstarts the whole production cycle. Factories follow either the original sketch or a tech pack provided by the designer. The idea is to solely review the style and design aesthetics, so it doesn’t need to be constructed adhering to the full specifications.

Any fabric and trim with similar weight can be used depending on its availability. Generally, three proto samples are made: two for the brand/designer's reference and one for the factory’s reference.

Digital garment sample

A digital sample is a software rendering of the garment in a 3D form which allows the visualization of fit and fall of the garment in both stillness and movement.

However, a complexed learning curve and high implementation cost can be the limiting factors of this technology. But if brands could overcome that, 3D can significantly cut down on sample making cost and approval time between the designers and factories.

Fit sample

As the name suggests, fit samples are to ensure the adequate fit and fall of the garments and they’re made in accordance with the sizing requested by the brand. Measurements and construction need to be accurate and correct in order to pass the fit evaluation. The fit sample can be made of a similar fabric as the one intended for the final design, and many adjustments could be necessary before the desired fit is achieved.

At this stage, you are only required to add specs for the sample size in your tech pack.

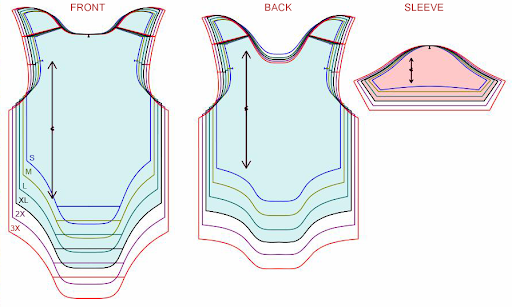

Size set sample

After the fit sample has been approved, the base pattern for each size need to be graded, so samples could be created for the entire size range. Size set sampling includes three samples of each size which are made with the fabric and finishings intended for the final product. After this is complete, mass production can start once the brand gives their approval to the factories.

Add exact specs of your entire size-range in your tech packs.

Salesman sample

As the name suggests, the salesman samples or SMS are the samples that are used for marketing and promotions of the product range. They are made with the final fabrics and final touches in the approved basic sizes. These are generally put on display in retail stores or exhibited at trade shows to get orders from respective retail channels.

GPT sample

GPT sample refers to the production sample that is given for "Garment Performance Test". These samples are used for a series of tests that a brand would like to evaluate before running the styles for production. The tests can include seam strength, seam slippage, colorfastness, wash fastness, among others.

Pre-production sample

A pre-production sample is the first sample made in the actual production line of the factory. It’s constructed with the actual fabrics intended for the design and trims with all the order specification regarding measurements, embroidery, and washes. It’s a test run by the factory and they can proceed with the bulk production only when the PP sample is approved by the brand.

Sealed sample

Once the PP sample is approved by the brand, they are sealed to prevent tampering from the factory and now become the standard for bulk production. They are also known as gold-seal samples or red-seal samples, depending on the approval, or disapproval of the brand.

TOP (Top of production) sample

After the approval of the PP sample, which signals the start of production, the Quality Control inspector representing a brand can visit the factory at any time and pick a garment from the production line for inspection. These samples are called "Top of production or TOP samples" and they are evaluated to ensure that the bulk production is of the same quality as the PP sample. TOP samples are also checked for their packaging.

Shipment sample

Once the bulk production is done and the shipment is finished, packed, and ready to go, a few samples are kept aside by the factory as shipment samples. These serve as to test the final product that will reach the brand; right from the folding to the packaging. Many brands will only approve shipping if the samples pass this test.

Press samples

Press samples are exact replicas of the final sellable product, usually in a model's sample size. They’re used for photographing promotional material like collection campaigns for advertising, look books, e-commerce and can be loaned to magazines for editorial photo shoots.

Other basic FAQ's

1. What is the difference between proto samples, fit samples, and pre-production samples?

These three types of garment samples represent different checkpoints in the product development timeline.

- Proto samples are made early to visualize the style and design intent.

- Fit samples help refine the garment’s measurements and construction for the desired fit.

- Pre-production samples (PP samples) are made on the actual production line with final materials to ensure everything is correct before bulk manufacturing begins.

For a full breakdown of how these samples fit into the overall manufacturing cycle, read our Ultimate Guide to Clothing Manufacturing and Pre-Production Sample Order Terms: A Complete Guide.

2. Why is sampling important in the garment production process?

Sampling is the bridge between design and production. It ensures that what’s designed on paper translates into a well-fitting, functional, and cost-effective product.

Skipping or rushing through sampling can lead to incorrect fits, high wastage, and customer dissatisfaction. Sampling also allows brands to check performance through tests like seam strength and colorfastness (using GPT samples).

To understand how samples contribute to a smooth manufacturing workflow, explore the Ultimate Guide to Clothing Manufacturing.

3. What role do tech packs play in garment sampling?

A tech pack acts as the blueprint for every garment sample — from proto to production. It includes technical specifications like measurements, construction details, materials, and trims that factories follow.

Without a complete tech pack, it’s difficult for factories to interpret your design correctly, leading to inconsistent samples.

Learn how to build one step-by-step in The Ultimate Guide to Tech Packs in Fashion.

You can also watch this quick tutorial on how to create a measurement fit sheet for your tech pack.

4. How are digital garment samples changing the way fashion brands work?

Digital sampling (3D samples) is transforming how brands visualize designs before physical production. Using 3D software, designers can simulate fabric drape, color variations, and fit on digital avatars.

This reduces physical sample iterations, speeds up approvals, and supports sustainable practices by minimizing material waste.

Many fashion teams now include digital prototypes in their tech packs — learn how in The Ultimate Guide to Tech Packs in Fashion.

5. What’s the difference between a sealed sample and a TOP (Top of Production) sample?

Once a pre-production (PP) sample is approved, it becomes the benchmark for the factory. It’s sealed and labeled — often called a gold seal or red seal sample.

During bulk production, quality inspectors randomly pick garments from the line — these are TOP samples. They’re checked against the sealed sample to ensure consistency in quality, construction, and packaging.

To learn more about how brands approve PP samples and manage production communication, check out Pre-Production Sample Order Terms: A Complete Guide.

6. How do brands manage size variations during sampling?

After the fit sample is approved, the garment pattern is graded into different sizes — creating size set samples for the full range.

Pattern grading ensures proportional accuracy across all sizes while maintaining the intended fit.

You can read more about how grading works inside Techpacker’s dedicated guide on pattern grading, and watch how to prepare your fit sheet for a tech pack.

7. How many samples are typically made before mass production starts?

On average, brands go through 5–7 rounds of sampling before the final bulk run. These include mock-ups, proto, fit, size set, PP, TOP, and sometimes press or shipment samples.

The number may vary depending on product complexity, materials, and brand standards.

For a detailed step-by-step overview of how samples fit into the manufacturing process, visit our Ultimate Guide to Clothing Manufacturing.